Hi guys,

I've got a fleet of diesel generators mounted on trailers, these are rental units used for emergency or temporary power supply, often used in remote regions with harsh road conditions like gravel, mud, potholes and unpaved roads. In addition, we also manufacture trailer-mounted generators for clients looking for a mobile solution.

Sizes differ from 10kVA to 250kVA, all in soundproof enclosures, and combined trailer-laden weight is approximately 1500kg to 4000kg. All trailers have brake systems and blade springs for suspension, blade springs are rated according to the designed laden weight. Some use single axles and we have double axles on larger units, no shock absorbers are fitted on the trailers. The generators are mounted onto a sturdy base fuel tank via anti-vibration rubber mountings, the failsafe type, all rated for the specific generator weight. Soundproof enclosures are also bolted down onto the rigid base tank. The whole assembly then bolts onto the trailer directly.

Most equipment such as PLCs, switchgear, batteries etc could handle large G-Loads. The trailer however as well as the anti-vibration rubber mounts has its limitations. My suppliers cannot advise on the exact limits that could safely be exerted onto these items before failure could occur. We've had several instances of stress-induced fractures on the trailers as well as sheared anti-vibration mountings. Often one can see where the axles bottomed out during these events where there's clear evidence of axle centre bolt marks on the trailer frame.

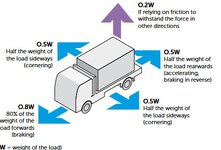

I've tested G-Loads recently with a datalogger when towing a generator, hard acceleration, hard stops, a few potholes and speedbumps, but this was all in the city on tarred roads, readings differ from 0.2 up to 0.6Gs. Off-road conditions would differ, same with rural roads and uneven loads when one axle carries more load than the other if the trailer hitch on the vehicle is too high or too low.

As generators go out frequently and often we have very little time to inspect a machine before sending it out again G-Load Dataloggers would not be a practical option to indicate possible damage that might require further investigation. I'm considering adding Shockwatch Impact Indicator stickers to all our units as well as retail units as a visual indication of potential damage. Unfortunately, I'm not sure what to go for, 1G, 2Gs, 5Gs? I'm an Electronic and Electrical engineer and have no idea about the Mechanical Engineering aspects and what would be considered "Safe" limitations.

If anyone could provide some insight or advice on what limits to work with I would truly appreciate it!

Thanks in advance.

I've got a fleet of diesel generators mounted on trailers, these are rental units used for emergency or temporary power supply, often used in remote regions with harsh road conditions like gravel, mud, potholes and unpaved roads. In addition, we also manufacture trailer-mounted generators for clients looking for a mobile solution.

Sizes differ from 10kVA to 250kVA, all in soundproof enclosures, and combined trailer-laden weight is approximately 1500kg to 4000kg. All trailers have brake systems and blade springs for suspension, blade springs are rated according to the designed laden weight. Some use single axles and we have double axles on larger units, no shock absorbers are fitted on the trailers. The generators are mounted onto a sturdy base fuel tank via anti-vibration rubber mountings, the failsafe type, all rated for the specific generator weight. Soundproof enclosures are also bolted down onto the rigid base tank. The whole assembly then bolts onto the trailer directly.

Most equipment such as PLCs, switchgear, batteries etc could handle large G-Loads. The trailer however as well as the anti-vibration rubber mounts has its limitations. My suppliers cannot advise on the exact limits that could safely be exerted onto these items before failure could occur. We've had several instances of stress-induced fractures on the trailers as well as sheared anti-vibration mountings. Often one can see where the axles bottomed out during these events where there's clear evidence of axle centre bolt marks on the trailer frame.

I've tested G-Loads recently with a datalogger when towing a generator, hard acceleration, hard stops, a few potholes and speedbumps, but this was all in the city on tarred roads, readings differ from 0.2 up to 0.6Gs. Off-road conditions would differ, same with rural roads and uneven loads when one axle carries more load than the other if the trailer hitch on the vehicle is too high or too low.

As generators go out frequently and often we have very little time to inspect a machine before sending it out again G-Load Dataloggers would not be a practical option to indicate possible damage that might require further investigation. I'm considering adding Shockwatch Impact Indicator stickers to all our units as well as retail units as a visual indication of potential damage. Unfortunately, I'm not sure what to go for, 1G, 2Gs, 5Gs? I'm an Electronic and Electrical engineer and have no idea about the Mechanical Engineering aspects and what would be considered "Safe" limitations.

If anyone could provide some insight or advice on what limits to work with I would truly appreciate it!

Thanks in advance.