reverbz

Structural

- Aug 20, 2024

- 80

Hey Guys,

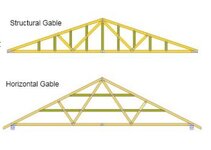

If you have a gable end truss on a single story house with a window or garage opening below, would you call for a drag truss on the plans? I don't really see a reason to do so but I've seen drawings with this done. I'd love to hear some thoughts on why this is done and if it's necessary.

Thank you!

If you have a gable end truss on a single story house with a window or garage opening below, would you call for a drag truss on the plans? I don't really see a reason to do so but I've seen drawings with this done. I'd love to hear some thoughts on why this is done and if it's necessary.

Thank you!