jerseyshore

Structural

- May 14, 2015

- 901

We are working on a splice detail to repair a 50 ft long glulam roof beam. The first 6 ft or so is completed damaged so the intention is to cut that part out and splice in a new matching member with a steel side plate on each side. The existing glulam is 6.5" wide x 32.5" deep.

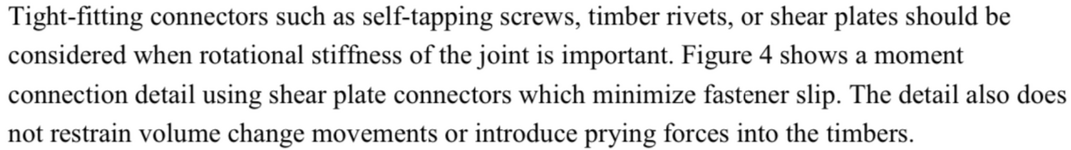

We've run some calcs and came up with about (12) 3/4" (2 rows of 6) bolts with 4" dia. shear plates required at both the top and bottom of the beam to resist the tension/ compression forces.

If we don't use the shear plates, we would need roughly (14) or (16) bolts in each zone. Might even have to bump up to 1" dia bolts.

We normally try to avoid wood moment connections at all cost, but are stuck with it here. Client obviously wants to minimize the splice cost as best as possible.

My question is, do we stick with the shear plates, even with the added cost, to reduce slip in this connection? Or do they not add any additional advantage here and just go ahead with adding the extra bolts?

We've run some calcs and came up with about (12) 3/4" (2 rows of 6) bolts with 4" dia. shear plates required at both the top and bottom of the beam to resist the tension/ compression forces.

If we don't use the shear plates, we would need roughly (14) or (16) bolts in each zone. Might even have to bump up to 1" dia bolts.

We normally try to avoid wood moment connections at all cost, but are stuck with it here. Client obviously wants to minimize the splice cost as best as possible.

My question is, do we stick with the shear plates, even with the added cost, to reduce slip in this connection? Or do they not add any additional advantage here and just go ahead with adding the extra bolts?