I have a small job to design a steel mount for a hanging sign (approx. 40 lbs) that is a 36" octagon shape. This is something new for me so I thought I might post a few questions.

1.) Calculated the wind loads using ASCE 7-10 eqn. 29.5-1 and Figure 29.5-1. Since the sign is simply hanging down I'm wondering if it flapping around in the wind like a flag might trigger some additional dynamic loading case or scenario that my current static approach is missing.

2.) Any suggestion on structural eye-bolts (McMaster Carr ?). Granted the weight of the sign is relatively light but the "Home Depot" (lag) eye-bolts are somewhat questionable at first glance, I'm thinking to treat the hardware (bolts, chains etc...) as lifting gear (ASME B30.20-2010) with its associated safety margins. I can't seem to find anything in the ASCE related to this sort of thing, probably looking in the wrong place though. Perhaps the steel manual...

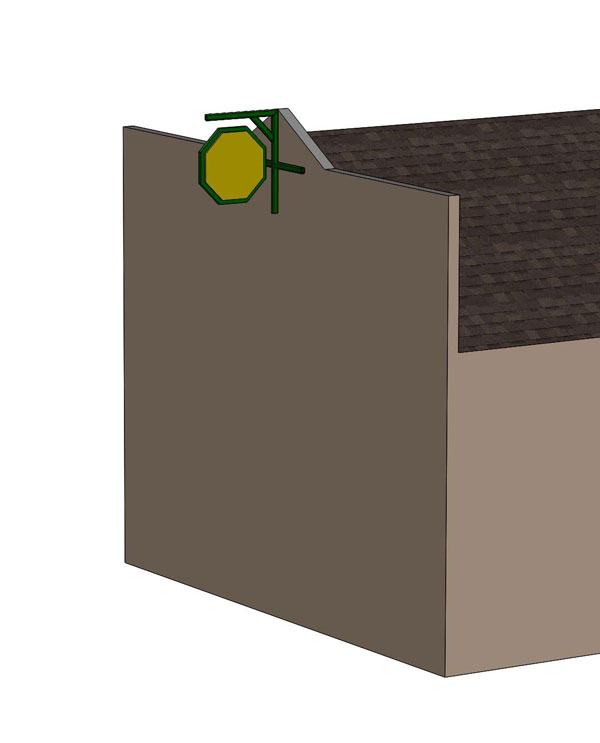

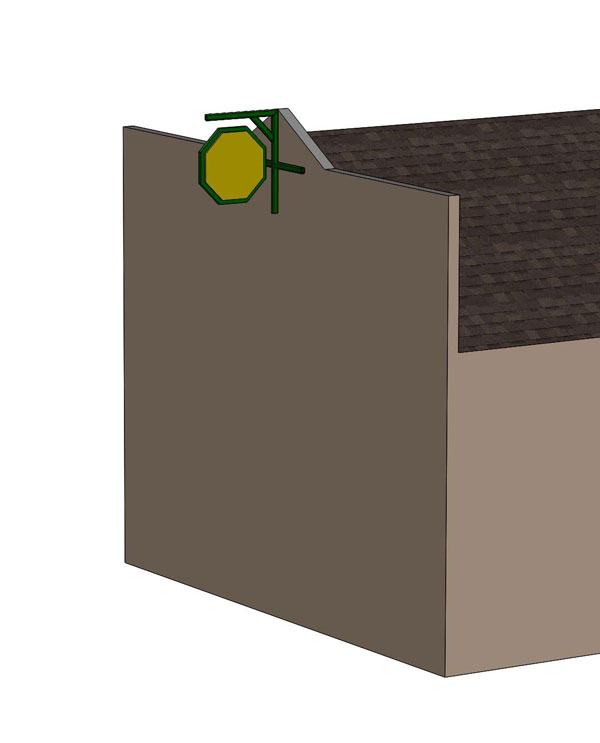

Below is a quick mock up of the design concept. Initially I thought to use pressure treated lumber but I think the welded rectangular HSS will give me a cleaner look.

A confused student is a good student.

Nathaniel P. Wilkerson, PE

1.) Calculated the wind loads using ASCE 7-10 eqn. 29.5-1 and Figure 29.5-1. Since the sign is simply hanging down I'm wondering if it flapping around in the wind like a flag might trigger some additional dynamic loading case or scenario that my current static approach is missing.

2.) Any suggestion on structural eye-bolts (McMaster Carr ?). Granted the weight of the sign is relatively light but the "Home Depot" (lag) eye-bolts are somewhat questionable at first glance, I'm thinking to treat the hardware (bolts, chains etc...) as lifting gear (ASME B30.20-2010) with its associated safety margins. I can't seem to find anything in the ASCE related to this sort of thing, probably looking in the wrong place though. Perhaps the steel manual...

Below is a quick mock up of the design concept. Initially I thought to use pressure treated lumber but I think the welded rectangular HSS will give me a cleaner look.

A confused student is a good student.

Nathaniel P. Wilkerson, PE