WendelTrento

Materials

Dear all,

Good afternoon,

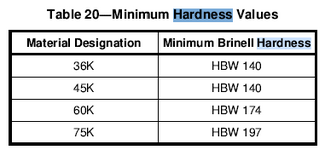

The API 6A standard specifies the minimum hardness values for carbon steels with a yield strength of 36K to 75K.

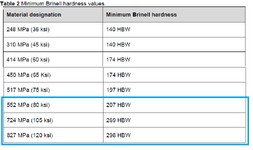

I have a hardness standard from a client that informs the minimum value for steels with a yield strength above the API.

Hardness standard text:

The minimum Brinell hardness values from ISO 10423 or API 6A [1], ISO 13628-4 [3] and API 17D [4] are given in Table 2.

Could you, if possible, inform me from which literature my client obtained these minimum hardness values for steels with a yield strength of 80ksi to 120ksi?

Att,

Wendel Trento

Good afternoon,

The API 6A standard specifies the minimum hardness values for carbon steels with a yield strength of 36K to 75K.

I have a hardness standard from a client that informs the minimum value for steels with a yield strength above the API.

Hardness standard text:

The minimum Brinell hardness values from ISO 10423 or API 6A [1], ISO 13628-4 [3] and API 17D [4] are given in Table 2.

Could you, if possible, inform me from which literature my client obtained these minimum hardness values for steels with a yield strength of 80ksi to 120ksi?

Att,

Wendel Trento