Ahmed Elarbagi

Petroleum

- Sep 12, 2024

- 5

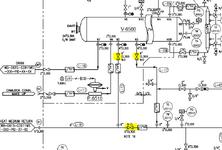

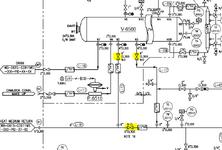

Hello everyone. I have been discussing a lot with different vendors and very experienced process engineers on hot oil systems. There is a lot of different opinions on whether or not hot oil should be normally flowing through the expansion tank.

Some propose that flowing through the expansion tank regularly is more logical; maintain pressure and allow for expansion as needed and not have to worry about pressure buildup due to thermal expansion as the expansion tank would have a PSV.

Some propose that the expansion tank should be bypassed and only one of the lines to it left normally open to account for expansions as needed.

Any thoughts on what the best practice is, and if reasons for why one approach is better than the other? Which of these valves would you NO and which NC, and why?

Some propose that flowing through the expansion tank regularly is more logical; maintain pressure and allow for expansion as needed and not have to worry about pressure buildup due to thermal expansion as the expansion tank would have a PSV.

Some propose that the expansion tank should be bypassed and only one of the lines to it left normally open to account for expansions as needed.

Any thoughts on what the best practice is, and if reasons for why one approach is better than the other? Which of these valves would you NO and which NC, and why?