Marlborough

Automotive

- Jun 21, 2008

- 35

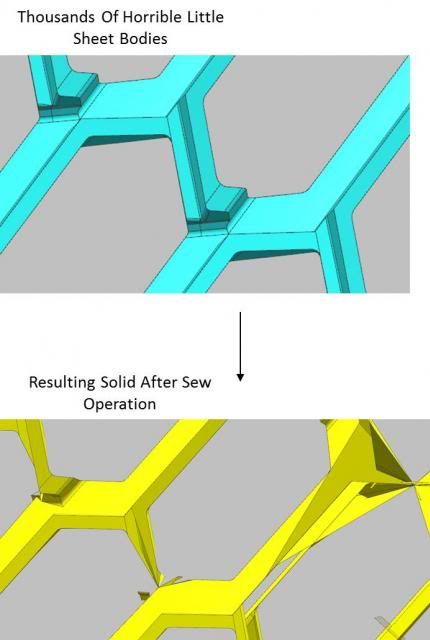

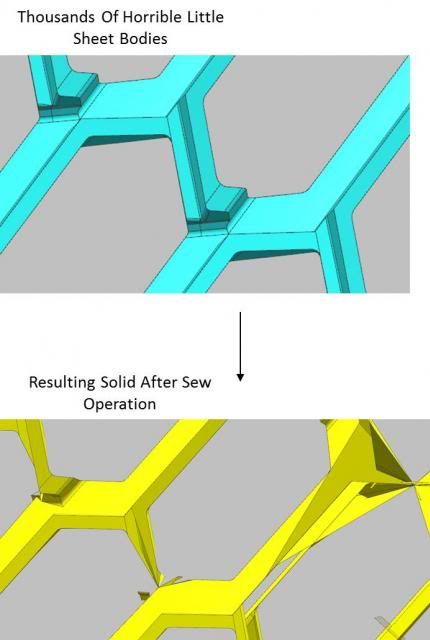

Help Converting Thousands Of Horrible Sheet Bodies To A Solid ( see jpeg )

So I just finished off a really unpleasant design project. Had to convert over 13,000 thousand poor quality unparametized studio sheet bodies into a solid. And by poor quality, I mean 80% of these sheets don't lineup edge to edge.

Sewing the sheets as is resulted in the image below. Took me over 3 weeks of recreating all the surfaces to finally obtain a usable solid body.

Can anyone think of a faster way of doing this ?

So I just finished off a really unpleasant design project. Had to convert over 13,000 thousand poor quality unparametized studio sheet bodies into a solid. And by poor quality, I mean 80% of these sheets don't lineup edge to edge.

Sewing the sheets as is resulted in the image below. Took me over 3 weeks of recreating all the surfaces to finally obtain a usable solid body.

Can anyone think of a faster way of doing this ?