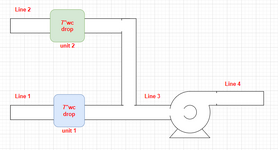

Imagine you have two ducts (ducts 1 and 2) that merge into a single duct (duct 3). There is a fan located on duct 3 that needs to pull air through ducts 1, 2, and 3, and then exhaust it through duct 4. Both ducts 1 and 2 have obstructions that cause a pressure drop of 7 inches of water column (7"wc) each. Assuming these obstructions are the only cause of pressure drop, would the fan need to generate a suction of 7"wc or 14"wc? I am trying to figure out how pressure drop works in series.

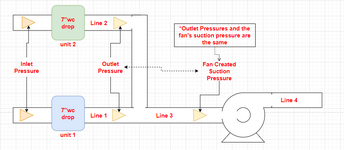

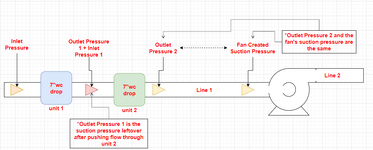

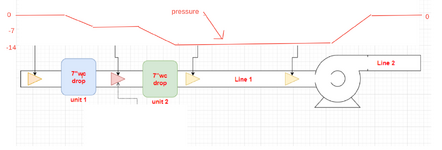

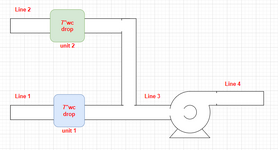

Hopefully this process diagram I made clarifies my imaginary setup and question.

edit: As it has been pointed out below, I was mistaken when I referred to the above setup as "in series". The setup is in parallel. I changed the title to avoid confusing anyone else who stumbles on this thread. Thank you to everyone who pointed that out to me.

Hopefully this process diagram I made clarifies my imaginary setup and question.

edit: As it has been pointed out below, I was mistaken when I referred to the above setup as "in series". The setup is in parallel. I changed the title to avoid confusing anyone else who stumbles on this thread. Thank you to everyone who pointed that out to me.

Last edited: