Hi all,

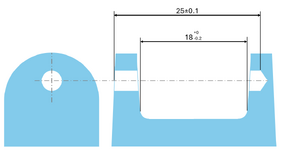

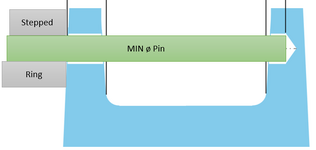

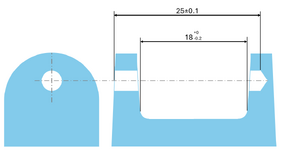

I have 2 dimensions which I hope to change to GD&T control. In the dwg represented below, dim 18 is meant to control the minimum width excluding root radius. Another part will fit in here.

(a) I'm thinking this can be controlled by Profile of surface (with unequal tol). Please advise if there is a better way to control?

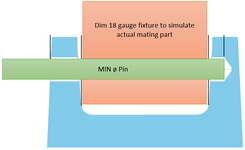

(b) Dim 25 is the length/depth of a hole and the intention is to control it excluding the tapered end. A rivet fits here by interference at left side. Can anyone suggest a way to define the FCF?

Thanks

YK

I have 2 dimensions which I hope to change to GD&T control. In the dwg represented below, dim 18 is meant to control the minimum width excluding root radius. Another part will fit in here.

(a) I'm thinking this can be controlled by Profile of surface (with unequal tol). Please advise if there is a better way to control?

(b) Dim 25 is the length/depth of a hole and the intention is to control it excluding the tapered end. A rivet fits here by interference at left side. Can anyone suggest a way to define the FCF?

Thanks

YK