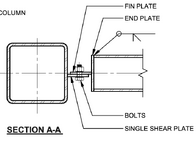

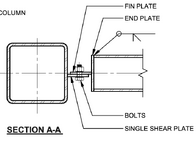

Hi everyone  , I'm designing a shear connection with a single plate between an HSS beam and an HSS column. I'm having doubts about what all the possible limit checks are for this type of connection.

, I'm designing a shear connection with a single plate between an HSS beam and an HSS column. I'm having doubts about what all the possible limit checks are for this type of connection.

I'm reviewing AISC 360-22 and the Manual, 16th edition for clarity, and I understand that the welding might govern here and that I have punching shear due to the single shear plate. But what other limit checks should I consider, for example, in the beam?

I'm reviewing AISC 360-22 and the Manual, 16th edition for clarity, and I understand that the welding might govern here and that I have punching shear due to the single shear plate. But what other limit checks should I consider, for example, in the beam?