r.borghino

Structural

- Nov 25, 2024

- 11

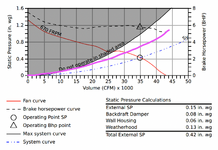

Structural engineer here, trying to figure out if the equipment in a small warehouse is appropriate. I own it and want to avoid retrofitting the ventilation. Looking through the data sheets they gave me, and running some basic numbers, the areas and air volume (CFM) through the inlets and outlets seem to match, but the inlet calculation does not include the filter pressure drop so I'm questioning the real air volume through the system to ensure 3 ach.

I have one outlet with an exhaust fan, which has a rated "Static Pressure" of 0.41 inH2O for the air volume (34k CFM) needed.

I have two inlets. Each is an assembly of a louver with a 1" filter. Each louver is 90" x 60", and has 12 filter panels installed to cover the louver area. The louver (without filter) has a rated "Pressure Drop" at the needed CFM of 0.09 inH2O. However, each filter panel (20"x20") reports a "Resistance" of 0.035 inH2O.

No ductwork. Just two inlets into a large rectangular room and one outlet.

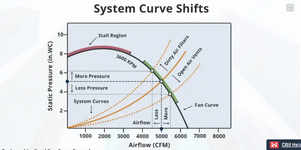

So.... I was hoping any of you would be able to point me in the right direction. My instinct was just to add the Louver and filter pressures, add that to the fan's pressure and get the new(real) CFM from the fan curve... but since these pressures are all called different (Static Pressure, Pressure Drop, Resistance) I don't know what to make of it.

I have one outlet with an exhaust fan, which has a rated "Static Pressure" of 0.41 inH2O for the air volume (34k CFM) needed.

I have two inlets. Each is an assembly of a louver with a 1" filter. Each louver is 90" x 60", and has 12 filter panels installed to cover the louver area. The louver (without filter) has a rated "Pressure Drop" at the needed CFM of 0.09 inH2O. However, each filter panel (20"x20") reports a "Resistance" of 0.035 inH2O.

No ductwork. Just two inlets into a large rectangular room and one outlet.

So.... I was hoping any of you would be able to point me in the right direction. My instinct was just to add the Louver and filter pressures, add that to the fan's pressure and get the new(real) CFM from the fan curve... but since these pressures are all called different (Static Pressure, Pressure Drop, Resistance) I don't know what to make of it.