EEENGRX

Electrical

- Sep 11, 2021

- 54

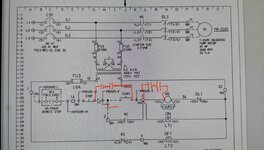

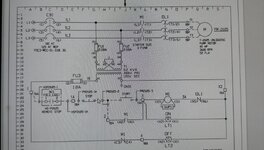

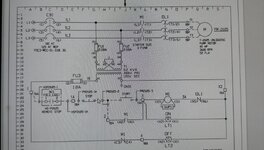

What would be the place place to install a float switch(SPDT) and a pressure switch to shut down a pump on low oil level and low pressure which would be LSL and PSL respectively considering the schematics below. I think this will be a series connection but I am thinking of installing them between the stop and start bottoms or between point 3 and M1as shown on the schematics. Let me know your thoughts and with reasons. Thanks

Last edited: