Chitina Jake

Industrial

- Mar 26, 2025

- 4

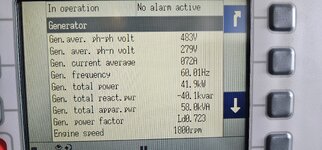

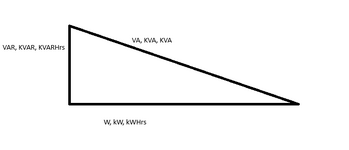

I provide O&M for a small remote utility in Alaska. we are an isolated grid with less than 100 customers, running john deere 4045 gensets, averaging 50KW. I have noticed that we have a PF of leading .7 and I wanted to correct it. one of my objectives is to "sell" the correction to my board of directors, and I wanted to try to include a fuel savings as well as equipment longevity. I have been researching the relationship between KW, KVA, KVAR and PF and I had a question relating KVA and KW:

If I were to correct my PF to .9, would that equate to a fuel savings because the engine doesn't have to produce the torque to create the extra VAR's? or is the KVA/KVAR to KW relationship purely theoretical to describe the difference in phase angle between the voltage and amps?

If I reduce my VAR's does the engine produce my KW more efficiently, so it consumes less fuel? we average 3GPH and at $3.50/gallon of fuel, I am looking to reduce costs as much as possible to keep electrical prices low

If I were to correct my PF to .9, would that equate to a fuel savings because the engine doesn't have to produce the torque to create the extra VAR's? or is the KVA/KVAR to KW relationship purely theoretical to describe the difference in phase angle between the voltage and amps?

If I reduce my VAR's does the engine produce my KW more efficiently, so it consumes less fuel? we average 3GPH and at $3.50/gallon of fuel, I am looking to reduce costs as much as possible to keep electrical prices low