From my container notes:

CONTAINERS

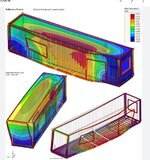

-ALL CONTAINERS SHALL BE SIMILAR SIZE, WEIGHT AND CONSTRUCTION.

-CONTAINERS SHALL BE FABRICATED TO ISO 1496-1990 EDITION MINIMUM.

-CONTAINER DESIGNATION SHALL BE 1D OR 1DX MINIMUM.

-CONTAINERS SHALL BE MINIMUM GRADE B, THESE ARE GENERALLY CONSIDERED AS CONTAINERS HAVING A FEW DENTS AND SCRATCHES, BUT CAN BE USED FOR STORAGE. THEY SHOULD NOT HAVE SUSTAINED MAJOR DAMAGE OR HAVE SIGNIFICANT CORROSION.

-CONTAINERS SHALL BE CERTIFIED AS CARGO WORTHY (CWO) AND WIND AND WATERTIGHT (WWT).

-CONTAINERS SHALL PASS THE FOLLOWING TESTS STIPULATED IN ISO 1496, U/N:

TEST 01- STACKING;

TEST 02- LIFTING FROM THE FOUR TOP CORNER FITTINGS;

TEST 03- LIFTING FROM THE FOUR BOTTOM CORNER FITTINGS;

TEST 04- RESTRAINT (LONGITUDINAL);

TEST 05- STRENGTH OF END WALLS;

TEST 06- STRENGTH OF SIDE WALLS;

TEST 07- STRENGTH OF ROOF;

TEST 08- FLOOR STRENGTH;

TEST 09- RIGIDITY (LONGITUDINAL);

TEST 10- RIGIDITY (TRANSVERSE);

TEST 11- LIFTING FROM FORKLIFT POCKETS;

TEST 12- LIFTING FROM THE BASE AT GRAPPLER ARM POSITIONS; AND

TEST 13- WEATHERPROOFNESS;

-IF LIFTING FROM THE FOUR BOTTOM CORNERS ONLY COMPLIANCE WITH TEST 02, TEST 11, AND TEST 12 CAN BE WAIVED.

-IF LIFTING FROM THE TOP CORNER CASTINGS COMPLIANCE WITH TEST 02 IS REQUIRED.

-THE FOLLOWING COATING SYSTEM IS RECOMMENDED. CLEANING SHALL BE TO SSPC-SP 1 AND SSPC-SP 6. PRIMER SHALL BE DEVOE 'DEVGUARD 4160 - MULTIPURPOSE TANK AND STRUCTURAL PRIMER'. TOPCOAT SHALL BE DEVOE 'SPEEDENAMEL 4318 - QD GLOSS ENAMEL' . COLOUR SELECTED BY OWNER.

-CONFORMANCE WITH ANY MECHANICAL OR ELECTRICAL REQUIREMENTS OF THE NATIONAL BUILDING CODE HAS NOT BEEN REVIEWED.

-CONFORMANCE WITH ANY REQUIREMENTS OF THE NATIONAL ENERGY CODE HAS NOT BEEN REVIEWED.

-CONTAINER DESIGN LOADS:

A 40’ SHIPPING CONTAINER HAS A TARE WEIGHT OF ABOUT 8159LBS AND A MAXIMUM CAPACITY OF ABOUT 59,039LBS. THE MAX LADEN WEIGHT IS ABOUT 67,199LBS.

Ss = 1.9KPA;

Sr = 0.2KPA;

q (WIND) = 6.4PSF (BASED ON 5 YEAR RETURN PERIOD, CALCULATED USING THE BC BUILDING CODE METHOD. IN THE EVENT OF A PUBLIC WEATHER ALERT FOR A SEVERE STORM EVENT, FROM ENVIRONMENT CANADA, PEOPLE SHALL DISTANCE THEMSELVES FROM THE SCREEN LOCATION;

Cg = 2;

Ce = 1;

Cp = 0.8 (WINDWARD);

Cp = 0.5 (LEEWARD);

CONTAINER WEIGHT = 5000 LBS MIN FOR 20’ CONTAINERS; AND

CONTAINER WEIGHT = 8250 LBS MIN FOR 40’ CONTAINERS.

-CONTAINER ATTACHMENT SHALL BE ACHIEVED BY USING METAL BANDING OR STRAPS FABRICATED FOR THIS PURPOSE.STRAPS SHALL BE PLACED AT 1/5 THE CONTAINER LENGTH FROM EACH END AND SHALL DEVELOP THE FOLLOWING MINIMUM LOAD CAPACITIES:

TOP CONTAINER TO INTERMEDIATE CONTAINER = 1000 LBS; AND

INTERMEDIATE CONTAINER TO BOTTOM CONTAINER = 2800 LBS.

-DEADLOAD, UNSHIFTABLE BALLAST SHALL BE PROVIDED FOR THE BOTTOM CONTAINERS. PROVIDE 64 PSF BALLAST FOR THE 20’ CONTAINERS, AND 82 PSF FOR THE 40’ CONTAINERS. THE AREA IS BASED ON INTERIOR FLOOR AREA OF THE LOWEST CONTAINER.

-CONTAINERS SHALL BE FOUNDED ON A GOOD COMPACTED GRANULAR BASE HAVING A BEARING RESISTANCE OF 2000 PSF MINIMUM.

-CONTAINER SUPPORT STRUCTURE IS INTENDED FOR SHORT DURATION LOADING ONLY AND NOT FOR OPERATION DURING THE WINTER SEASON.

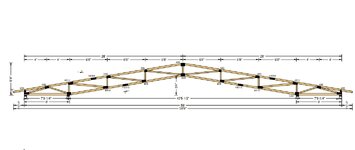

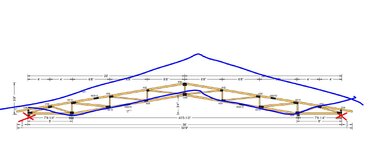

-THE SCREEN SUPPORTING TRUSSES, SUPPORTED ON THE TOP HAVE BEEN REVIEWED FOR STATIC LOADS ONLY. THEY SHALL NOT BE SECURED AT THE BASE (THIS WILL INCREASE THE VERTICAL LOADING ON THE TRUSSES. THE ENDS OF THE TRUSSES SHALL BE SECURED TO THE CONTAINERS AND SUITABLE BEARING PROVIDED.

You need to get a copy of ISO 1496.