Zoobie777

Chemical

- Jun 28, 2022

- 28

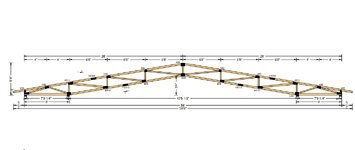

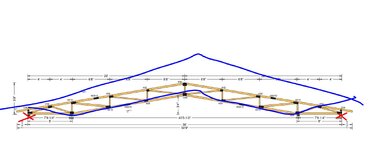

I have designed several roof truss systems for garages/storage buildings constructed with seacans as the 'walls'. They are increasingly popular, especially with homesteaders. Most of the time the trusses bear on the walls with a sill plates running up the 40' (or 20') sides. We have a customer asking for a 4' spacing option for a roof with a 40' clear span between the containers. This is resulting in bearing reactions on the inside bearings of 5200 lbf unfactored/7300 lbf factored. While the building design is outside of my scope, I am wondering if there is a maximum point load for this type of construction. Will a single or double SPF plate distribute the load sufficiently? I found out what the weight of a seacan roof can hold (~57000 lbs) but not sure how that translates into max plf for the wall. Also, is there an appreciable difference in capacity between a normal seacan (8'-6" tall) and a high cube (9'-6" tall)?

Thanks for any info/advice you may have.

Cheers!

Thanks for any info/advice you may have.

Cheers!