Sharkbiteattack

Mechanical

- May 6, 2013

- 15

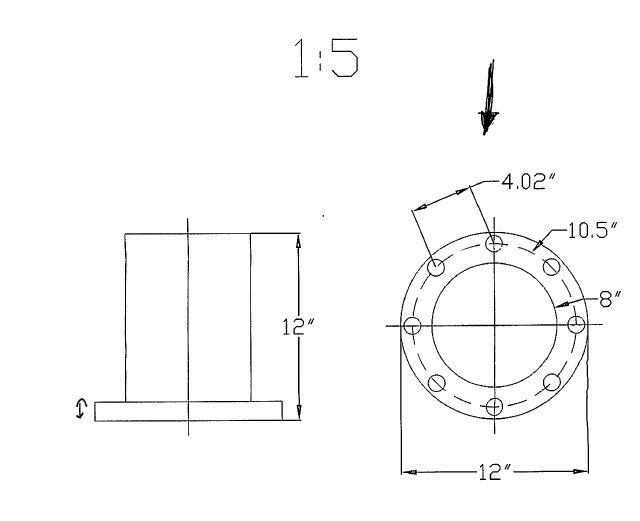

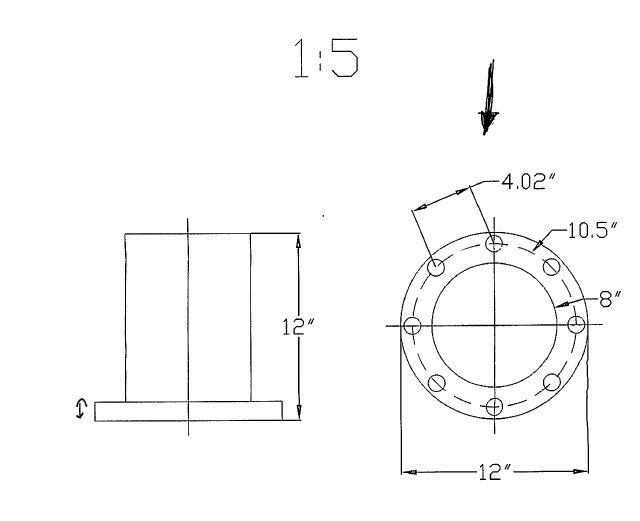

This ductile iron pipe is connected with others vertically in water. Doesn't look like anything standard. Most 8" pipes have an 11.75" diameter bolt center and a 13.50" flange. Everyone at work is stumped! ![[ponder] [ponder] [ponder]](/data/assets/smilies/ponder.gif)

![[ponder] [ponder] [ponder]](/data/assets/smilies/ponder.gif)