r.borghino

Structural

- Nov 25, 2024

- 11

Hello!

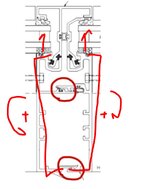

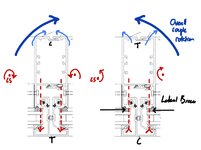

Context: We have a question regarding assumptions for a unitized curtain wall, where the main structural component is a male/female aluminum beam assembly. Typical spans anywhere from 10ft to 15ft.

-The usual assumption by contractors (which we think is incorrect) is to assume that each half-profile is fully braced and Lb=0, or that Lb=distance to nearest snap joint clip (Lb=roughly 2ft). Or Lb=L/3. Assuming the "brace" is infinitely stiff.

-If I check by ADM 2020, evaluating each "half-profile" independently, the allowable moment for LTB decreases drastically, which I also think is not a reasonable evaluation. (having witnessed a few wind load tests already for these types of profiles - LTB is only an issue for only the most slender of shapes where they are already well outside the allowable deflections anyway)

The Problem: Some options, some better than others.

1.- We were suggested to calculating the LTB moment using the slenderness formula for "Closed Shape" (F.4.2.3), but plugging in the J, Ix and Iy of the male and female halves added together. Lb= real distance to nearest transverse profile.

2.- under certain loading conditions (positive wind pressure) the compression flange is arguably actually continuously braced against LTB by the structural adhesive bonding with the glass and LTB becomes a non-issue. Therefore, LTB is a problem only for negative wind pressure.

3.- Still going through the Yura papers

Do you have any pointers or experience with these cases? Thanks!

Context: We have a question regarding assumptions for a unitized curtain wall, where the main structural component is a male/female aluminum beam assembly. Typical spans anywhere from 10ft to 15ft.

-The usual assumption by contractors (which we think is incorrect) is to assume that each half-profile is fully braced and Lb=0, or that Lb=distance to nearest snap joint clip (Lb=roughly 2ft). Or Lb=L/3. Assuming the "brace" is infinitely stiff.

-If I check by ADM 2020, evaluating each "half-profile" independently, the allowable moment for LTB decreases drastically, which I also think is not a reasonable evaluation. (having witnessed a few wind load tests already for these types of profiles - LTB is only an issue for only the most slender of shapes where they are already well outside the allowable deflections anyway)

The Problem: Some options, some better than others.

1.- We were suggested to calculating the LTB moment using the slenderness formula for "Closed Shape" (F.4.2.3), but plugging in the J, Ix and Iy of the male and female halves added together. Lb= real distance to nearest transverse profile.

2.- under certain loading conditions (positive wind pressure) the compression flange is arguably actually continuously braced against LTB by the structural adhesive bonding with the glass and LTB becomes a non-issue. Therefore, LTB is a problem only for n

3.- Still going through the Yura papers

Do you have any pointers or experience with these cases? Thanks!