safaeng

Materials

- Aug 29, 2010

- 9

Hello

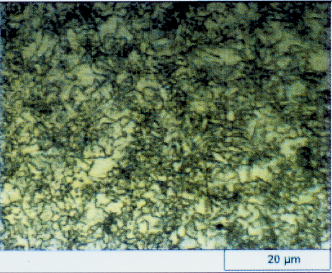

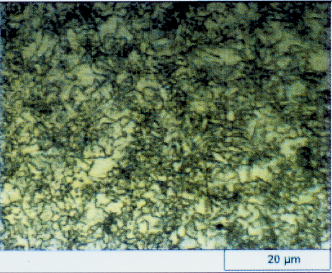

I am looking for some help on this picture (attached)

Ii is a resistance spot welded metal. Actually this picture is taken from the HAZ near to Weld metal.

The base metal structure is ferrite and pearlite and the chemical composition is :

C 0.15

Mn 1.02

Si 0.2

P, S, Al, Co, ~ 0.006

Mo 0.002

Cr 0.01

Cu 0.04

and the weld metal structure is martensite.

In this picture the steel is etched by 2% nital solution.

The laboratory told me the structure is ferrite grains with regions of pearlite, small particles of cementite and a little tempered martensite.

I know that the bright matrix is ferrite phase, can anyone tell me what part is pearlite or tempered martensite?

Do the laboratory told me the truth?

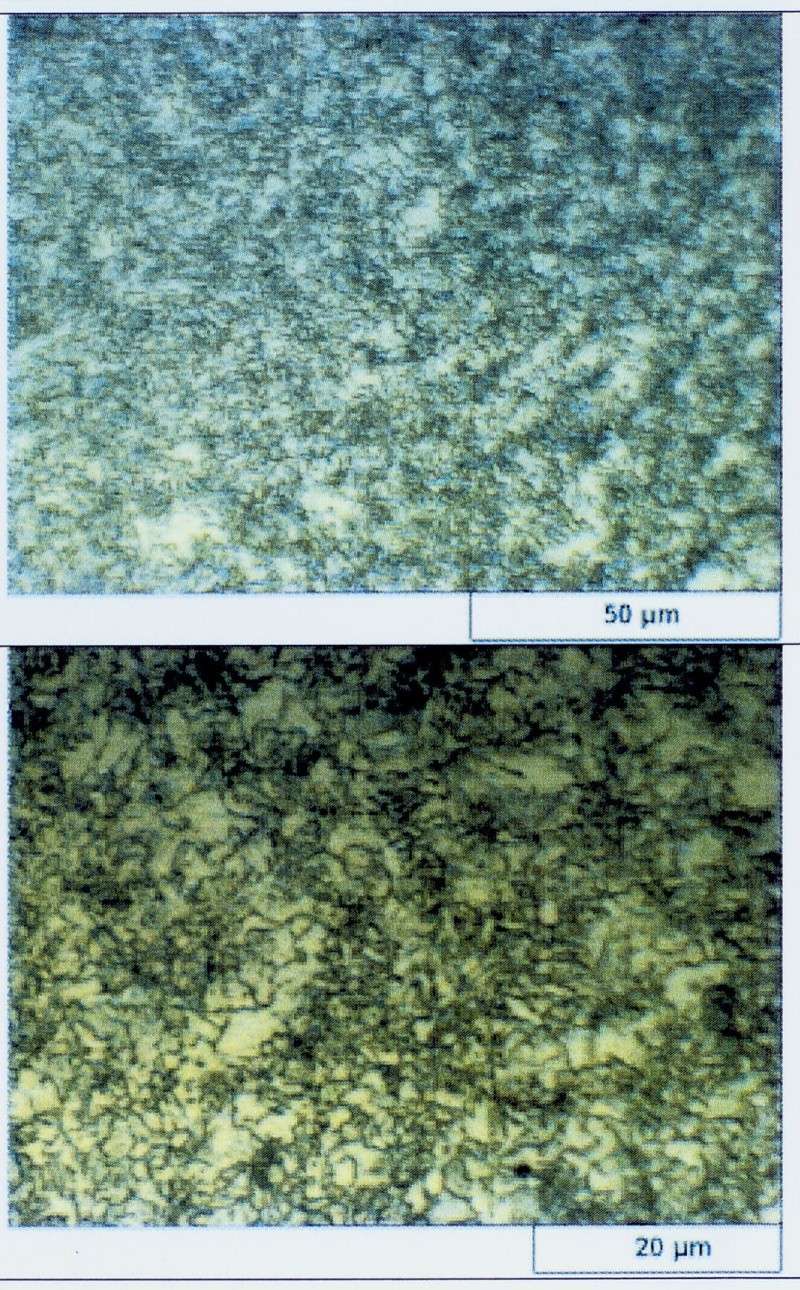

I am looking for some help on this picture (attached)

Ii is a resistance spot welded metal. Actually this picture is taken from the HAZ near to Weld metal.

The base metal structure is ferrite and pearlite and the chemical composition is :

C 0.15

Mn 1.02

Si 0.2

P, S, Al, Co, ~ 0.006

Mo 0.002

Cr 0.01

Cu 0.04

and the weld metal structure is martensite.

In this picture the steel is etched by 2% nital solution.

The laboratory told me the structure is ferrite grains with regions of pearlite, small particles of cementite and a little tempered martensite.

I know that the bright matrix is ferrite phase, can anyone tell me what part is pearlite or tempered martensite?

Do the laboratory told me the truth?