EngDM

Structural

- Aug 10, 2021

- 452

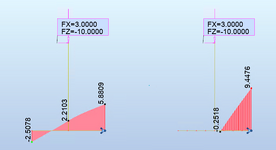

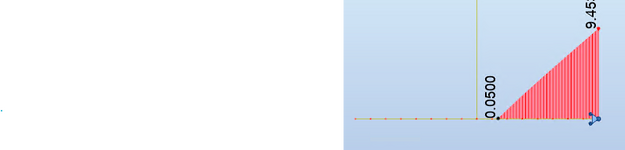

I've got a slab that has some discrete tension/shear points that I've been running in SAFE. To get the design footprint I inputted my subgrade modulus and ran the slab, and increase the slab thickness/footprint until I no longer was getting positive bearing values, I.E. slab doesn't uplift.

I was watching a video on creating an envelope for the soil pressure, and the presenter converted all of the load cases to nonlinear load cases, and now when I run my slab I don't have uplift pressures, it only displays as 0; it is only showing where the slab pushes down on the soil with no indicator (other than it being zero) that the slab may be in uplift.

I'm just curious as to what this non-linear case actually performs, and if I should have converted my cases to non-linear at all. I was never taught to do that by my co-workers.

Also, after converting to non-linear, my load combinations are no longer defined by my load cases, but have been "flattened" into a single one, so to convert back to linear I apparently have to re-type all of my load cases...

I was watching a video on creating an envelope for the soil pressure, and the presenter converted all of the load cases to nonlinear load cases, and now when I run my slab I don't have uplift pressures, it only displays as 0; it is only showing where the slab pushes down on the soil with no indicator (other than it being zero) that the slab may be in uplift.

I'm just curious as to what this non-linear case actually performs, and if I should have converted my cases to non-linear at all. I was never taught to do that by my co-workers.

Also, after converting to non-linear, my load combinations are no longer defined by my load cases, but have been "flattened" into a single one, so to convert back to linear I apparently have to re-type all of my load cases...