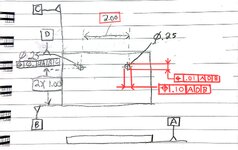

I have a part that is mounting an object to it via two holes. The hole on the left is my "primary" hole in the pattern. Don't REALLY care where it lands. The hole on the right, I want tied to the first hole. I need its vertical tolerance controlled very tightly (.01 positional), but I am able to loosen the horizontal tolerance (+/-.10). My original thought was to use datums A, D, and B in the feature control frame, but then I realized that I don't have a basic dimension going between the right hole and datums D. So would the correct feature control frame only reference datums A and B? Is there anything to be gained out of including D as the secondary datums? Or would I be better off using a two single segment feature control frame?