Asisraja D

Mechanical

- Jan 3, 2024

- 187

Hi Professionals

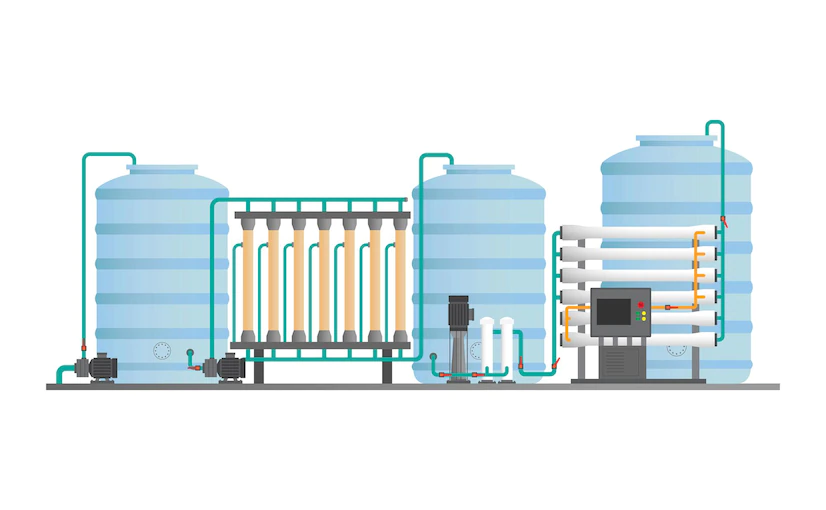

I need your help in designing purified water generation system to our plant, we are manufacturing API product and we have set 4000 LPH RO system as a feed water for PW generation system but i don't have further how to develop the process and arrange things to initiate the design ? like after RO feed water what are the steps are involved in Purified water generation system. does anyone give your experience in this for me ?

I need your help in designing purified water generation system to our plant, we are manufacturing API product and we have set 4000 LPH RO system as a feed water for PW generation system but i don't have further how to develop the process and arrange things to initiate the design ? like after RO feed water what are the steps are involved in Purified water generation system. does anyone give your experience in this for me ?