Asisraja D

Mechanical

- Jan 3, 2024

- 193

Hi professionals

![[bigsmile] [bigsmile] [bigsmile]](/data/assets/smilies/bigsmile.gif)

"Strive for perfection in everything you do. Take the best that exists and make it better. When it does not exist, design it." - Sir Henry Royce

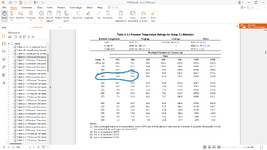

i am a project engineer and i did some calculations part for calculating wall thickness for pipes under internal pressure as per ASME B31.3.

i have attached the sheet here.

This is just my work to submit to all of you for a review on the steps involved here and the Units i used here whether right or wrong ?

if anyone cross check the work please you can download and try this at free time. Thank you for all of your support to keep curious of engineering as part of my life.

i have attached the sheet here.

This is just my work to submit to all of you for a review on the steps involved here and the Units i used here whether right or wrong ?

if anyone cross check the work please you can download and try this at free time. Thank you for all of your support to keep curious of engineering as part of my life.

![[bigsmile] [bigsmile] [bigsmile]](/data/assets/smilies/bigsmile.gif)

"Strive for perfection in everything you do. Take the best that exists and make it better. When it does not exist, design it." - Sir Henry Royce

![[thumbsup] [thumbsup] [thumbsup]](/data/assets/smilies/thumbsup.gif)