PT99

Structural

- Apr 24, 2007

- 62

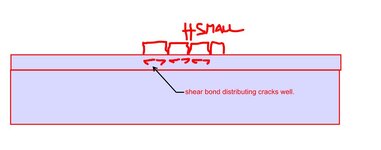

THIS IS A MULTI LEVEL TYPICAL PARKING STRUCTURE (OPEN SIDES) WITH PRECASET DOUBLE T's. I AM CONSIDERING FOR TOPPING SLAB TO USE 1 1/2" THICK LATEX MODIFIED CONCRETE WITH 6X6 W2.9XW2.9 WWR. ANY COMMENTS. LOCATION IS SOUTHERN US.

ANY SUGGESTIONS?

ANY SUGGESTIONS?