Hi everybody! First post, so please bear with me. I have a problem with my car for years. Out of experience I can say that almost all problems with card can be solved by sitting on the sofa and keep thinking hard enough, but this one got the best of me. I need ideas... so here it goes:

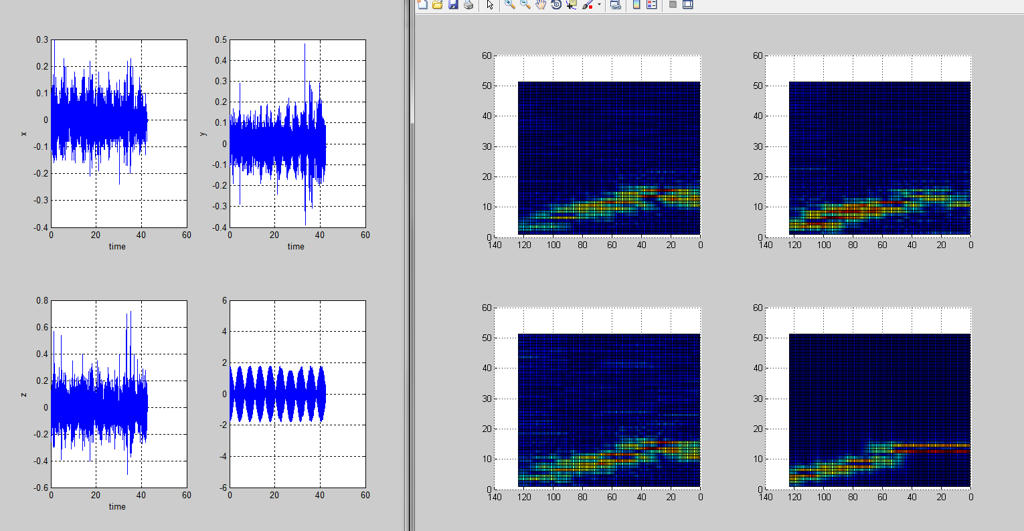

Periodic vibration at higher speeds. Starting at about 110 km/h (70 miles/h) and gets stronger and faster up to 140 km/h (90 miles/h). It starts to smooth out over that speed and barely noticeable from 170-180 upwards (yes, in Europe). The vibration is pretty strong , shakes the change in the glove box, shakes the entire body of the car, seats, dashboard, everything.

It is periodic with a wavelength of about 3-4 seconds at 140 km/h. The length depends on the speed of the car AND NOTHING ELSE! So it shakes, gets smooth and shakes again.

What effects it? Barely anything except the quality of the pavement. If that is smooth (concrete) the vibration is less. The car has a stick shift, 5 speed, an inline 6 cylinder engine built in with two monts. There is a mont under the transmission as well. The differential is mounted to the body of the car. The drive shaft is made from two pieces, coupeling to the transmission and the differential with flexible disks. The two pieces joins in the middle of the car where it is supported by a small bearing. There is also a u-joint next to it.

The shaking won't change for a gear change so the engine speed is indifferent. It won't change for an open or closed clutch either! It won't change for bends in the road or braking and accelerating. The road surface has some effects.

I am lost. Tires are changed multiple times, rims (steel) were rotated, suspention elements, tie rods, shocks, shock mounts, steering elements all had been changed. Flex disks and drive shaft bearing had been changed. These all had minor effects if any, problem is still there.

Can this be a motor mount problem? What could cause a periodic vibration or what method is right to go after this. It might be even a suspension problem, nothing to do with the drive train! What would you do next? Can this be a combination of vibrations it being periodic but very predictable?

Thanks for all your inputs.

Periodic vibration at higher speeds. Starting at about 110 km/h (70 miles/h) and gets stronger and faster up to 140 km/h (90 miles/h). It starts to smooth out over that speed and barely noticeable from 170-180 upwards (yes, in Europe). The vibration is pretty strong , shakes the change in the glove box, shakes the entire body of the car, seats, dashboard, everything.

It is periodic with a wavelength of about 3-4 seconds at 140 km/h. The length depends on the speed of the car AND NOTHING ELSE! So it shakes, gets smooth and shakes again.

What effects it? Barely anything except the quality of the pavement. If that is smooth (concrete) the vibration is less. The car has a stick shift, 5 speed, an inline 6 cylinder engine built in with two monts. There is a mont under the transmission as well. The differential is mounted to the body of the car. The drive shaft is made from two pieces, coupeling to the transmission and the differential with flexible disks. The two pieces joins in the middle of the car where it is supported by a small bearing. There is also a u-joint next to it.

The shaking won't change for a gear change so the engine speed is indifferent. It won't change for an open or closed clutch either! It won't change for bends in the road or braking and accelerating. The road surface has some effects.

I am lost. Tires are changed multiple times, rims (steel) were rotated, suspention elements, tie rods, shocks, shock mounts, steering elements all had been changed. Flex disks and drive shaft bearing had been changed. These all had minor effects if any, problem is still there.

Can this be a motor mount problem? What could cause a periodic vibration or what method is right to go after this. It might be even a suspension problem, nothing to do with the drive train! What would you do next? Can this be a combination of vibrations it being periodic but very predictable?

Thanks for all your inputs.