Zeyad Zahran

Student

- Nov 7, 2024

- 4

Hello everyone,

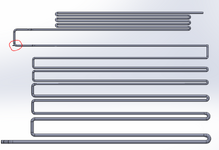

I am investigating a problem of the bowing of the lower tubes of a VDU fired heater, what are the best approaches to prevent or mitigate this phenomenon.

I am investigating a problem of the bowing of the lower tubes of a VDU fired heater, what are the best approaches to prevent or mitigate this phenomenon.