Jack.C

Industrial

- Feb 17, 2023

- 18

Hi,

Kindly asking for your help on belows query.

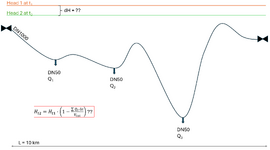

Let's assume a 10km long DN1000 pipeline with 3 drains at the low points. The initial head is H1 (orange line).

After a time step dt a certain amount of water has left the system (I'm using the Toricelli approach) through the 3 drains.

How would you calculate the head drop / new head H2 in the system? I would like to avoid a complex numerical equation to calculate the drop but rather go with a simplified approach.

Our simplified approach is shown in the red box in the below figure.

Please note that we are aware that the head line will behave different for the individual sags once it is equal to the height of the profile. So at one point Q1 and Q2 will drain the sag 1 whereas Q3 will drain sag 2 and that there will be different heads in these section. This will be considered.

Your inputs would be highly appreciated.

Thanks and regards!

Kindly asking for your help on belows query.

Let's assume a 10km long DN1000 pipeline with 3 drains at the low points. The initial head is H1 (orange line).

After a time step dt a certain amount of water has left the system (I'm using the Toricelli approach) through the 3 drains.

How would you calculate the head drop / new head H2 in the system? I would like to avoid a complex numerical equation to calculate the drop but rather go with a simplified approach.

Our simplified approach is shown in the red box in the below figure.

Please note that we are aware that the head line will behave different for the individual sags once it is equal to the height of the profile. So at one point Q1 and Q2 will drain the sag 1 whereas Q3 will drain sag 2 and that there will be different heads in these section. This will be considered.

Your inputs would be highly appreciated.

Thanks and regards!