HDStructural

Structural

- Apr 24, 2024

- 110

Hello all,

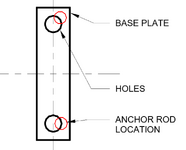

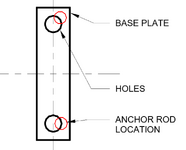

I am working on a small project where we are replacing a few anchors due to anchor misplacement. We will be using an adhesive anchor system. The problem that I am having is that the anchors are only off by 3/4" or so, and are in the way of where the new anchors would be.

Is it possible to do a large core drill of the concrete area (maybe 2" or 3" diameter) that would contain the existing anchor rod. Then epoxy in a new anchor? The issue I see is that the whole would be way too large.

Could I have them roughen the surface around the hole then fill it with concrete/grout and just place the anchor bolt in? Due to the left/right eccentricity of the anchors, we cannot just slot the base plate holes.

What have been your best solutions for these situations?

I am working on a small project where we are replacing a few anchors due to anchor misplacement. We will be using an adhesive anchor system. The problem that I am having is that the anchors are only off by 3/4" or so, and are in the way of where the new anchors would be.

Is it possible to do a large core drill of the concrete area (maybe 2" or 3" diameter) that would contain the existing anchor rod. Then epoxy in a new anchor? The issue I see is that the whole would be way too large.

Could I have them roughen the surface around the hole then fill it with concrete/grout and just place the anchor bolt in? Due to the left/right eccentricity of the anchors, we cannot just slot the base plate holes.

What have been your best solutions for these situations?