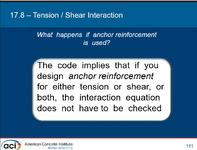

I'll keep it short...half the hardware vendors and consulting engineers say combined shear and tension should be checked for lifting hardware, other half say it doesn't apply. Sometimes it controls.

Assuming its origin is in ACI Ch. 17, there is a disclaimer in the first paragraph of the chapter: "Safety levels specified are intended for in-service conditions rather than for short-term handling and construction conditions." There is also the 4:1 safety factor specified in OSHA 1926.704, which is further straying from ACI Ch. 17.

I feel comfortable not checking it when such a large safety factor is used for tension and shear capacities, and a recent check of an anchor using Ch. 17 calculations showed it passed when maxed out in tension and shear, but the catalog-listed capacities are more conservative.

Any precast or tilt-up folks able to weigh in?

Assuming its origin is in ACI Ch. 17, there is a disclaimer in the first paragraph of the chapter: "Safety levels specified are intended for in-service conditions rather than for short-term handling and construction conditions." There is also the 4:1 safety factor specified in OSHA 1926.704, which is further straying from ACI Ch. 17.

I feel comfortable not checking it when such a large safety factor is used for tension and shear capacities, and a recent check of an anchor using Ch. 17 calculations showed it passed when maxed out in tension and shear, but the catalog-listed capacities are more conservative.

Any precast or tilt-up folks able to weigh in?