AD_1979

Mechanical

- Mar 6, 2023

- 18

Dear all,

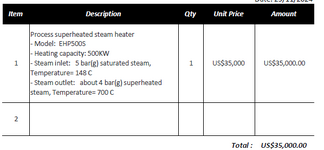

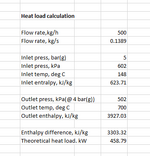

Due to an application we need to organize in one of our facilities, we need to deal with the production of a quantity of around 500 kg/h of a really high temperature steam (Around 700 C). Is there any way of doing this? I can get steam up to 450 C....but I cannot find any alternative / technology for getting this extra boost of temperature.

Your help is really appreciated.

Regards,

AD

Due to an application we need to organize in one of our facilities, we need to deal with the production of a quantity of around 500 kg/h of a really high temperature steam (Around 700 C). Is there any way of doing this? I can get steam up to 450 C....but I cannot find any alternative / technology for getting this extra boost of temperature.

Your help is really appreciated.

Regards,

AD