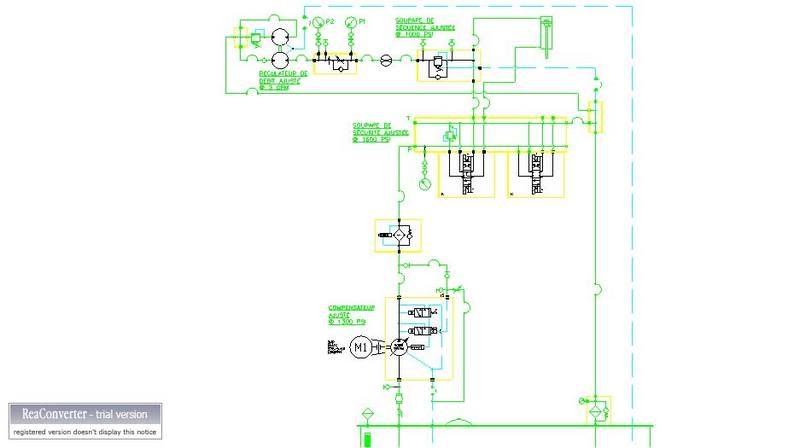

Hi all, Could anyone familiar with these valves (Hytos in this case) help me figure out why the following happens: I have a hydraulic circuit where the principal components are: pump, Hytos proportional directional valve with closed center, a sequence valve which will actuate a cylinder (on extention) and when the cylinder reaches stroke end, the gear motor starts running (flow is now being diverted to it by the sequence valve). However, when doing the inverse procedure, when I move the valve past its center, therefore starting the retraction stroke of the cylinder( as the proportional control is turned from full flow paralel paths, to center and then moving towards cylinder retraction (crossed paths), the motor will start running albeit at a slower speed untill the cylinder is completely retracted and the gear motor then stops. I know its related to the differences between a proportional valve and an on/off one, but I just can't put my finger on it.

Thanks

Thanks