FlashPurp

Industrial

- May 10, 2024

- 14

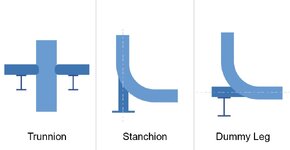

Hello, We have SCH10S piping and have various structural supports welded to it (dummy legs, base supports, etc.) Because it is thinner pipe, do we need to include repads? Concern would also be the weld burns through the thin wall.

Will CAESAR II be able to check this somehow? Or what recommendation would there be to validate results/findings?

Will CAESAR II be able to check this somehow? Or what recommendation would there be to validate results/findings?