mark512

Mechanical

- Aug 4, 2017

- 34

I've been scouring textbooks and the internet regarding roll center heights, and in particular the front-rear difference (roll axis inclination) and why the rear roll center is often higher than the front. I've organized what I found into several theories:

Theory 1 - Other suspension requirements are more important and the RC's just happen to fall out of the numbers:

Front RC Low - The front axle steers, so low RC, long equivalent swing arm lengths means predictable steering due to minimal track change, minimal RC height change, minimal camber change with suspension motion, minimal jacking forces, etc.

Rear RC High - In the case of live axle, Watts linkage or Panhard rod determines roll center, and needs to be high to avoid physically scraping the road. In the case of IRS, needs to be higher especially in the case of RWD where keeping the wheels square to the road / squarer to the road than the front is important.

Discarded Theory - Roll moment distribution: I've seen a lot of this type of explanation on forums, and it makes sense that it affects the roll moment distribution if you literally hold everything else constant and only vary the roll axis inclination, but there are many other ways to adjust the distribution other than by purely roll center heights.

Unhelpful Theory - The rear roll center needs to be higher than the front because it makes the car "feel right"

Interesting Theory - This one apparently comes from Maurice Olley, that roll axis inclination controls roll-yaw coupling, and that having the RCH higher in the rear stabilizes the vehicle by causing yaw in the opposite direction of the turn as the car rolls.

Theory 2 - Geometric weight transfer "kick in the rear end"

Front RC Low - The weight transfer in the front end is almost entirely elastic, so starts small and builds with body roll

Rear RC High - The high roll center means lots of nearly instantaneous geometric weight transfer at the rear end, causing transient oversteer that compensates for other sources of (perceived) steering sluggishness.

There was an explanation on this forum by NormPeterson that seems to jive with this theory (in particular, combining this with high(er) front roll stiffness to have initial oversteer that transitions to limit understeer.) Also, looking at some race car setups (non-downforce) plus a detailed analysis of the Ferarri F355 suspension that's floating around the internet, it seems that if this interpretation is correct, quite a few designers subscribe to it - putting the front roll center slightly above or slightly below ground level, with the rear more substantially (~100mm-200mm) above ground.

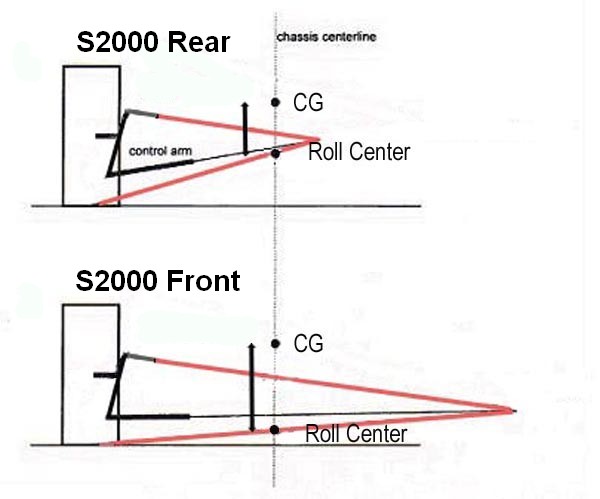

The question then becomes how much of a "kick in the rear end" is necessary? The AP1 (first gen) Honda S2000 seems to subscribe to this, with a rear roll center 190mm above ground, however many have described this car as "trying to kill you." The Ferarri F355 and NA (first gen) Mazda Miata both have their rear roll centers at 120mm above ground (though the Miata front RC is high at 60mm) and I've heard no such complaints about these.

I'd be very interested in your thoughts on the validity of these theories and assumptions. Thanks!

Theory 1 - Other suspension requirements are more important and the RC's just happen to fall out of the numbers:

Front RC Low - The front axle steers, so low RC, long equivalent swing arm lengths means predictable steering due to minimal track change, minimal RC height change, minimal camber change with suspension motion, minimal jacking forces, etc.

Rear RC High - In the case of live axle, Watts linkage or Panhard rod determines roll center, and needs to be high to avoid physically scraping the road. In the case of IRS, needs to be higher especially in the case of RWD where keeping the wheels square to the road / squarer to the road than the front is important.

Discarded Theory - Roll moment distribution: I've seen a lot of this type of explanation on forums, and it makes sense that it affects the roll moment distribution if you literally hold everything else constant and only vary the roll axis inclination, but there are many other ways to adjust the distribution other than by purely roll center heights.

Unhelpful Theory - The rear roll center needs to be higher than the front because it makes the car "feel right"

Interesting Theory - This one apparently comes from Maurice Olley, that roll axis inclination controls roll-yaw coupling, and that having the RCH higher in the rear stabilizes the vehicle by causing yaw in the opposite direction of the turn as the car rolls.

Theory 2 - Geometric weight transfer "kick in the rear end"

Front RC Low - The weight transfer in the front end is almost entirely elastic, so starts small and builds with body roll

Rear RC High - The high roll center means lots of nearly instantaneous geometric weight transfer at the rear end, causing transient oversteer that compensates for other sources of (perceived) steering sluggishness.

There was an explanation on this forum by NormPeterson that seems to jive with this theory (in particular, combining this with high(er) front roll stiffness to have initial oversteer that transitions to limit understeer.) Also, looking at some race car setups (non-downforce) plus a detailed analysis of the Ferarri F355 suspension that's floating around the internet, it seems that if this interpretation is correct, quite a few designers subscribe to it - putting the front roll center slightly above or slightly below ground level, with the rear more substantially (~100mm-200mm) above ground.

The question then becomes how much of a "kick in the rear end" is necessary? The AP1 (first gen) Honda S2000 seems to subscribe to this, with a rear roll center 190mm above ground, however many have described this car as "trying to kill you." The Ferarri F355 and NA (first gen) Mazda Miata both have their rear roll centers at 120mm above ground (though the Miata front RC is high at 60mm) and I've heard no such complaints about these.

I'd be very interested in your thoughts on the validity of these theories and assumptions. Thanks!