SocklessJ

Structural

- Aug 24, 2017

- 50

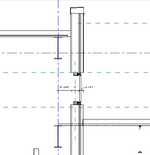

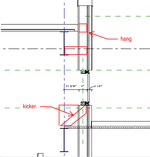

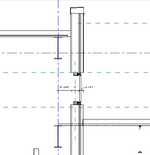

I have a new steel building with an 8’ roof step. The wall is CFS with metal panel cladding, and runs parallel to the joists. It’s also offset from the gridline. There’s a 22’ wide ribbon window.

1. What’s the best way to support the wall? I could:

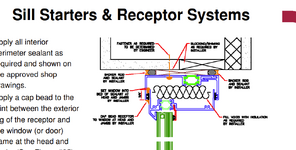

2. Should I add HSS headers and jambs for the ribbon window, or can the cold formed engineer deal with this? I assume 22’ is too long to span a cold-formed header, but maybe he can hang it from above if I provide torsional restraint to my beam.

See snapshot below (ignore that the wall is shown extending down through the deck.)

1. What’s the best way to support the wall? I could:

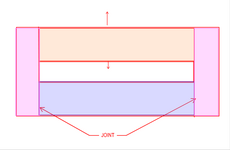

a. Bear the wall on the roof deck. I haven’t checked the deck for web crippling, but just don’t like the idea. Deck is 22ga.

b. Add another joist under the wall and block the flutes. Seems a little weird to have two beams 14” apart, but otherwise I think this could work.

c. Add perpendicular beams and run a gigantic bent plate to catch the wall and still get the diaphragm shear back to the gridline.

2. Should I add HSS headers and jambs for the ribbon window, or can the cold formed engineer deal with this? I assume 22’ is too long to span a cold-formed header, but maybe he can hang it from above if I provide torsional restraint to my beam.

See snapshot below (ignore that the wall is shown extending down through the deck.)