Inchtain

Petroleum

- Feb 21, 2021

- 145

Dear Gents,

We are going to perform a general turnaround for an NGL Plant.

I would like to know if it is mandatory by code/standard to dismantle the safety valves pertaining to the equipment planned for inspection during the period of the shutdown for inspection and setting verification.

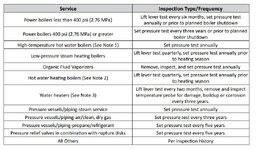

As far as I know, API 510 allows a 5-yr interval for safety valves inspections. Can we refer to that if we skip their inspections to save time?

If the safety valves haven't been recalibrated at the time of the equipment inspection, can be that a cause for the rejection of certifying the equipment by a third party?

Thanks and best regards,

We are going to perform a general turnaround for an NGL Plant.

I would like to know if it is mandatory by code/standard to dismantle the safety valves pertaining to the equipment planned for inspection during the period of the shutdown for inspection and setting verification.

As far as I know, API 510 allows a 5-yr interval for safety valves inspections. Can we refer to that if we skip their inspections to save time?

If the safety valves haven't been recalibrated at the time of the equipment inspection, can be that a cause for the rejection of certifying the equipment by a third party?

Thanks and best regards,