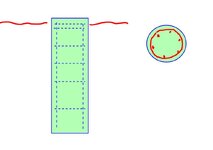

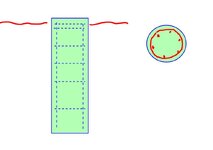

I've got some piles that were constructed without being inspected. Some testing was done to confirm the pile depth but I'm being told that it is not possible to scan the rebar from the top of the pile in order to ascertain at least the rebar circle (right side sketch below).

Is is problematic to scan pile rebar from the top? The verticals will be more important than the ties for this.

Is is problematic to scan pile rebar from the top? The verticals will be more important than the ties for this.