Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JStephen on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

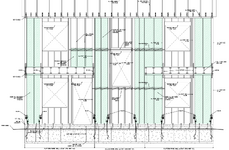

shear wall opening in mid floor 2 stories

- Thread starter 1ARCO5

- Start date

- Status

- Not open for further replies.

- Thread starter

- #3

In these solutions, What is the chord member of the diaphragm? The top plate breaks at the balloon framed walls.

That said, I would look at this using Force Transfer Around Openings from a calculation perspective. This would likely eliminate the need for the hold-downs at the upper floor shear walls but would require a strap above and below the opening. At most, you would only need five hold-downs into the foundation. On the diaphragm of the upper floor, I would break up into at least three separate diaphragms, depending on the floor plan. This would eliminate the need for a continuous chord member across the front.

I would recommend sheathing the whole front of the house. We just ignore the walls at the balloon frame from a calc perspective.

That said, I would look at this using Force Transfer Around Openings from a calculation perspective. This would likely eliminate the need for the hold-downs at the upper floor shear walls but would require a strap above and below the opening. At most, you would only need five hold-downs into the foundation. On the diaphragm of the upper floor, I would break up into at least three separate diaphragms, depending on the floor plan. This would eliminate the need for a continuous chord member across the front.

I would recommend sheathing the whole front of the house. We just ignore the walls at the balloon frame from a calc perspective.

Attachments

Is this allowed as per O86? I didn't think you could use non-full height shear walls and use FTAO?

Is this allowed as per O86? I didn't think you could use non-full height shear walls and use FTAO?

But the FTAO walls are full height? If you're able to post the particular clause that concerns you, I might be able to speak to it more directly.

Clause 11.4.1.1 of O86:19 does not allow the sheathing above and below openings to be considered in the shearwall resistance. The way you have coloured the SW pink seems to indicate relying on that sheathing. Per CSA, don't you have to provide holddowns at each end and each side of openings (if required and not offset by gravity loads).But the FTAO walls are full height? If you're able to post the particular clause that concerns you, I might be able to speak to it more directly.

Not sure if OP is practicing in Canada, but if I am interpretting the code incorrectly it would be great to actually be able to use FTAO.

Not sure if OP is practicing in Canada

I'm always speaking American unless it's a thread specifically targeted to a different market.

Moreover, you've really read more into my proposed solution than I intended to convey. What I was going for was this:

a) Here's a load path through the part of this that's convoluted.

b) Here's a chunk of easy wall that looks viable as lateral bracing for the rest.

It was never really my intent to speak to the minutia of the design or construction of the easy bit.

it would be great to actually be able to use FTAO.

Meh. In my heart, I've never fully bought into the more exotic shear wall design methods. I feel that there is merit in keeping it simple. So I'm happy to have the exotic stuff neutered above the 49th. It's one of those things where, once you can do fancy stuff, you sort of have to do fancy stuff.

I can't speak about Candain code.... I have done a 20,000 ft review of the BCBC code, but that is about it.

What sold me on the FTO method was an older engineer took four pieces of paper out and cut a square hole in them. On two of them, he took a piece of tape and placed it on the four corners of the open. Then he passed two of them two me. We both took the one without tape and placed it on a glass tabletop. Then, with one palm on the top and the other on the bottom, we applied an in-plane force in the opposite direction, forcing the sheet to tear from the corners of two opposing corners, resulting from the deflection. We then did the same for the ones with tape. It took about twice the force to rip this sheet at the opening corners.

Years later, I study this method in detail in Terry Malone's book The Analysis of Irregular Shaped Structures Diaphragms and Shear Walls. A few years later, the American Wood Association released an Excel spreadsheet for this force calculation. See this link: apawood.org/ftao. This method is well accepted here in the States and is backed up by research, even for areas with high seismic forces, such as the West Coast.

I am interested in how partitioners north of the 49th practice structural engineering.

I look forward to reading your responses here and elsewhere.

What sold me on the FTO method was an older engineer took four pieces of paper out and cut a square hole in them. On two of them, he took a piece of tape and placed it on the four corners of the open. Then he passed two of them two me. We both took the one without tape and placed it on a glass tabletop. Then, with one palm on the top and the other on the bottom, we applied an in-plane force in the opposite direction, forcing the sheet to tear from the corners of two opposing corners, resulting from the deflection. We then did the same for the ones with tape. It took about twice the force to rip this sheet at the opening corners.

Years later, I study this method in detail in Terry Malone's book The Analysis of Irregular Shaped Structures Diaphragms and Shear Walls. A few years later, the American Wood Association released an Excel spreadsheet for this force calculation. See this link: apawood.org/ftao. This method is well accepted here in the States and is backed up by research, even for areas with high seismic forces, such as the West Coast.

I am interested in how partitioners north of the 49th practice structural engineering.

I look forward to reading your responses here and elsewhere.

Ironically, the most recent and significant research on FTAO was done as a collaboration between USDA Forest Products Laboratory and the University of British Columbia. For the benefit of my geo-challenged friends in parts afield, the University of British Columbia is in Canada. So you'd think that we'd be on board.

The anecdote certainly has curb appeal. That said, I question the validity of the experiment. Ripping the opening corners of a piece of paper is going to be 100% fracture mechanics rupturing. I would expect an FTAO wall to "fail" by way of fastener slip induced, excess drift. You may open the corner some, but I don't seem them being "ruptured".

It took about twice the force to rip this sheet at the opening corners.

The anecdote certainly has curb appeal. That said, I question the validity of the experiment. Ripping the opening corners of a piece of paper is going to be 100% fracture mechanics rupturing. I would expect an FTAO wall to "fail" by way of fastener slip induced, excess drift. You may open the corner some, but I don't seem them being "ruptured".

And that's why CANAM joists are different members for every single member. I feel bad for people who put RTU's on roofs in the future when most of the joists are dialed in on each member, makes it a pain to measure up.It's one of those things where, once you can do fancy stuff, you sort of have to do fancy stuff.

- Status

- Not open for further replies.

Similar threads

- Question

- Replies

- 15

- Views

- 12K

- Question

- Replies

- 2

- Views

- 612

- Locked

- Question

- Replies

- 12

- Views

- 8K

- Replies

- 0

- Views

- 2K

- Replies

- 1

- Views

- 2K