XR250

Structural

- Jan 30, 2013

- 5,737

What's y'all's take on this...

ssttoolbox.widen.net

ssttoolbox.widen.net

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

and also be aware that the supply of many of the fancier Simpson products aren't readily supplied to Canada.

I tried billing in Simpson Strong Frames once and they almost had a stroke with the price so I dropped it down to CCQM's/hour.Well if JerseyShore can bill in Simpson Strong-Links instead of hangers, they may be useful

The seismic version is actually unique I believe in that the yielding mechanism is included in the connection elements. Sideplate and kaiser brackets still have a yielding beam element. For wind I can't really see why this is economical other than its easy to design.At first glance, isn’t this just competition for Sideplate? I’d be more surprised if Simpson got into the business of structural fuses.

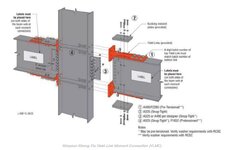

Know if the system below can be got in BC? Andy Metten discussed it in a SEABC course that I'm taking presently.