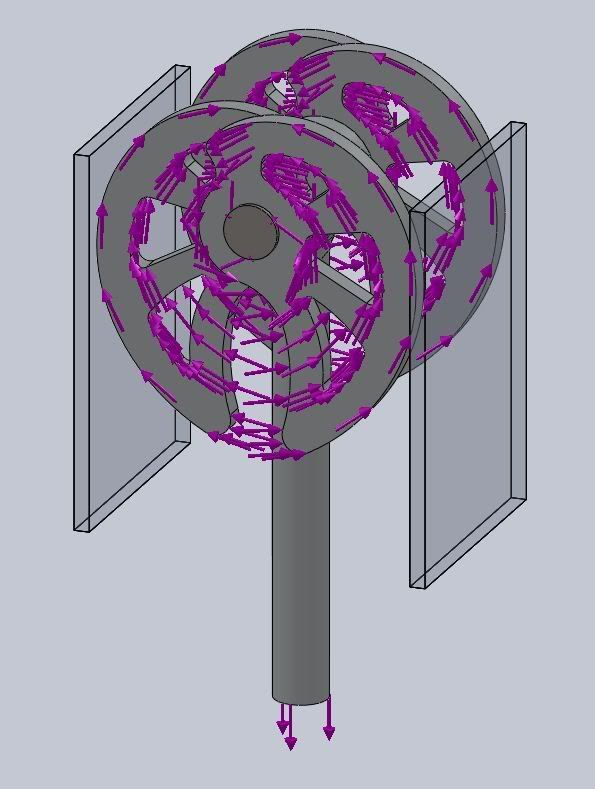

I am trying to model and optimize a piece of climbing equipment called a 'cam', but am struggling to get an accurately restrained study to solve.

I have been able to do so by fixing a few small faces near where the points of contact would be, but that is not very accurate as the restrained faces actually strengthen the assembly.

The more accurate method it to use 2 parallel walls with defined contact to the cam lobes. I have tried this as many ways as I can think: no penetration (with specified friction), penetration, bonded, shrink fit, with and without large displacement flagged, with the walls 'fixed' completely, with them as a set material and only the outer face as fixed geometry.

Most of my effort has gone into a static study, but I have even tried it as a non-linear to help ramp the main force in smoothly, since the frictional force is a function of it. No go. I get failures ranging from a 'study failed' to 'incremental elastic strain too large', and other vague failures.

Basically, in real life, a spring preloads the lobes into the wall. the main axle pivot sits above the plane made by the lobe contact points (at the camming angle). As downward force is applied to the main stem, more force is redirected outwards into the walls, generating more frictional force and eventually bending the lobes and axle. I have tried using defined friction (between the lobes and wall) from .4 up to 1. I have preloaded the lobes with force on a particular set of faces nearly parallel to the walls, and also as a torque on the lobes.

What am I missing here guys? Are the study types I am using not suited for this situation?

Any help would be GREATLY appreciated! I'm sure you know how much time you can burn up waiting hours only to come back to a failed study!

I have been able to do so by fixing a few small faces near where the points of contact would be, but that is not very accurate as the restrained faces actually strengthen the assembly.

The more accurate method it to use 2 parallel walls with defined contact to the cam lobes. I have tried this as many ways as I can think: no penetration (with specified friction), penetration, bonded, shrink fit, with and without large displacement flagged, with the walls 'fixed' completely, with them as a set material and only the outer face as fixed geometry.

Most of my effort has gone into a static study, but I have even tried it as a non-linear to help ramp the main force in smoothly, since the frictional force is a function of it. No go. I get failures ranging from a 'study failed' to 'incremental elastic strain too large', and other vague failures.

Basically, in real life, a spring preloads the lobes into the wall. the main axle pivot sits above the plane made by the lobe contact points (at the camming angle). As downward force is applied to the main stem, more force is redirected outwards into the walls, generating more frictional force and eventually bending the lobes and axle. I have tried using defined friction (between the lobes and wall) from .4 up to 1. I have preloaded the lobes with force on a particular set of faces nearly parallel to the walls, and also as a torque on the lobes.

What am I missing here guys? Are the study types I am using not suited for this situation?

Any help would be GREATLY appreciated! I'm sure you know how much time you can burn up waiting hours only to come back to a failed study!