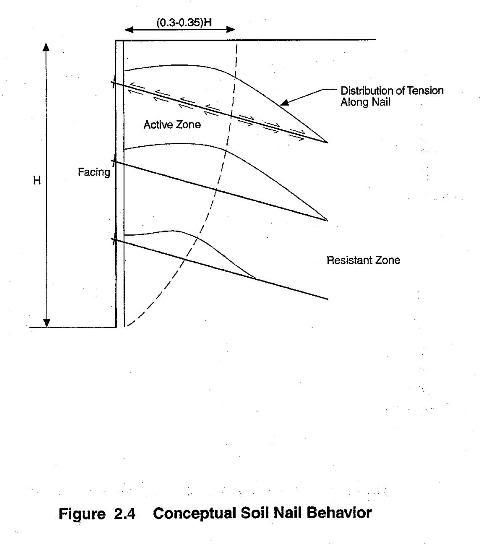

Soil nails include a tendon that is enveloped by grout that develops shear along the grout-soil interface. Soil screws include a shaft with helicies (sp) at varying locations. Between the helicies there is limited shear capacity along the shaft-soil interface.

Consider the image below:

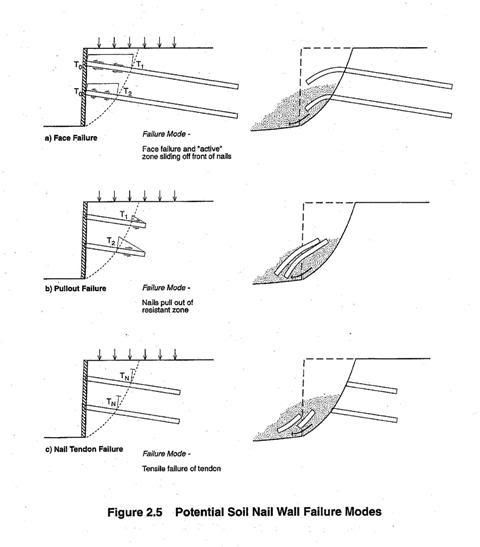

Consider potential failure modes:

I would think that the soil screw doesn't work quite the same.

Comments?

f-d

¡papá gordo ain’t no madre flaca!

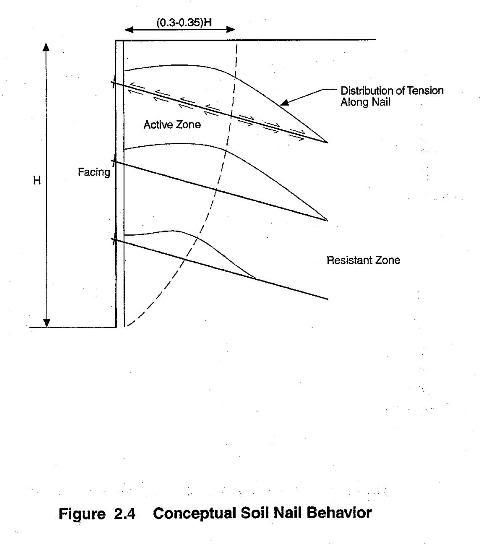

Consider the image below:

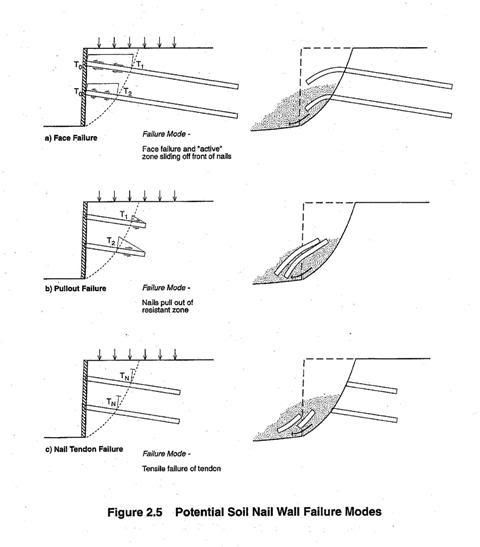

Consider potential failure modes:

I would think that the soil screw doesn't work quite the same.

Comments?

f-d

¡papá gordo ain’t no madre flaca!