SE2607

Structural

- Sep 24, 2010

- 272

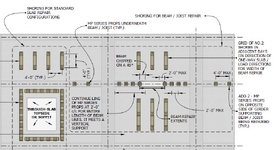

I'm going to look at a situation where a concrete beam has spalled concrete and the owner would like to repair it. I don't have any issue with doing this. I would probably specify something like Sika Dur Hi Mod 32 for a bonding agent, but my concern is, unless I shore the beam to relieve the load, the new concrete won't help much except for any live load that might be applied after the repair. I've never specified shoring of a concrete beam before. Is that practical? Any other thoughts?

TIA

TIA