JStructsteel

Structural

- Aug 22, 2002

- 1,441

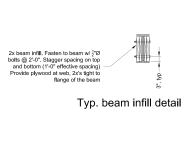

Contractor wants to do face hangers on infill inside the steel beam. Do you folks think a detail showing the wood bearing on the flange is required, otherwise the cross grain capacity isnt that good. I have some longer spans, and also some beams framing into the sides. At beam hangers, would possibly need to have web stiffeners too.