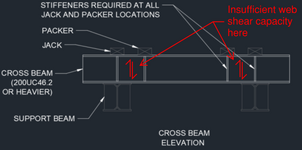

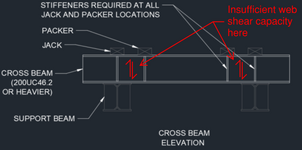

I have a situation where we are using a grillage of steel beams to temporarily support and jack up another structure. There are separate jacking points and packers along the cross beams; when the jack is at the end of its stroke length, the load will be transferred to the packers and the jacks will be reset, then repeat.

When the load is supported on the jacking points, there is a direct vertical load path to the support beams beneath, and the bearing failure is handled by adding a pair of vertical stiffeners - pretty straightforward stuff.

The problem is when the load is transferred to the packers. We can provide vertical stiffeners to handle the bearing issue. But the problem I am having now is that the proposed section does not have enough shear capacity (web capacity alone) - refer to below sketch.

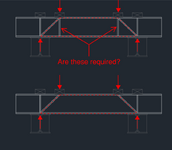

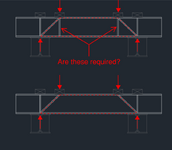

Without necessarily increasing the section size (because the bending capacity is more than enough), I'm wondering if there is a simpler solution in just adding a pair of diagonal stiffeners that will provide a kind of strut-and-tie system as below:

A few questions:

*In general, is the overall idea sound? Am I missing something obvious here?

*I would intend to check the diagonal struts in a similar manner as is normally done for the vertical stiffeners, i.e., separate yielding and buckling checks based on an equivalent column section. Any issues with that approach?

*If we have diagonal stiffeners providing a direct load path, do we need the vertical stiffeners below the packer locations? (I assume yes because there is still the possibility of yielding/buckling of the web, but would like to hear a few others' opinions).

*Would there be any particular buckling check required for the top flange (assuming it is a compact section)?

Would greatly appreciate any help, thanks

When the load is supported on the jacking points, there is a direct vertical load path to the support beams beneath, and the bearing failure is handled by adding a pair of vertical stiffeners - pretty straightforward stuff.

The problem is when the load is transferred to the packers. We can provide vertical stiffeners to handle the bearing issue. But the problem I am having now is that the proposed section does not have enough shear capacity (web capacity alone) - refer to below sketch.

Without necessarily increasing the section size (because the bending capacity is more than enough), I'm wondering if there is a simpler solution in just adding a pair of diagonal stiffeners that will provide a kind of strut-and-tie system as below:

A few questions:

*In general, is the overall idea sound? Am I missing something obvious here?

*I would intend to check the diagonal struts in a similar manner as is normally done for the vertical stiffeners, i.e., separate yielding and buckling checks based on an equivalent column section. Any issues with that approach?

*If we have diagonal stiffeners providing a direct load path, do we need the vertical stiffeners below the packer locations? (I assume yes because there is still the possibility of yielding/buckling of the web, but would like to hear a few others' opinions).

*Would there be any particular buckling check required for the top flange (assuming it is a compact section)?

Would greatly appreciate any help, thanks