1) Incoming and outgoing bar force the same.

I do not agree. Most experiments are done on a single bar pulled on one side, so the other leg has a force of 0... and still increasing the bend diameter helps.

Look at this paper for example:

https://www.sciencedirect.com/scien...?ref=pdf_download&fr=RR-2&rr=8e6288f0eac7ec22

Equation 11 shows clearly that the force transferred by the bend is proportional to the mandrel diameter even when there is no tension in one of the legs.

PS. Keep in mind that this discussion is only about the bend + tail part... consider that you have exactly the same length of the first straight part and the same bar diameter.

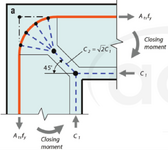

I do feel that you are wrong in this particular case. Increasing the bend diameter makes for a gentler delivery of bar stress but, as far as I know, does not change the assumed stress condition at the nodal faces.

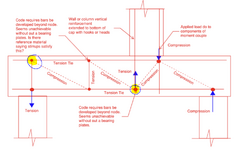

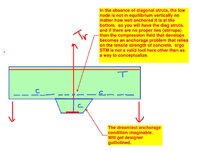

It does not if you look at it code-wise, a CTT node is still a CTT node. But if you look at it code-wise you can anchor it any way you want, it does not mention anything that you're talking about. So we need to talk about the actual physics. Again, look at the paper, now equation (8) and text before it. Stresses inside a bend need to be checked for the local crushing of concrete - stress is deviation stress / diameter of a bar. Is this not the crushing of a strut that is forming? Is it something else?

Now look at equation (A.16) - deviation stresses at the curved part of the bar... larger the bend diameter, smaller the deviation stresses.

In other words, larger the bend diameter is, less probable it is that concrete will crush. Since in equation (8) strength is the same it means that a diagonal strut has a different dimension. It may not be a huge difference, I don't know.

I do not agree that a larger bar / bar bend improves anything here.

Oh I never said that a larger bar is better. I'd use the smallest bar possible, but I would use a mandrel diameter of 6D and reduce the anchorage length by around 15% (based on the code) without worrying too much about it.

It is not the case that, because small hooks are okay, large hooks are okay.

We completely agree in this respect. But you chose 5D as an OK bend diameter, but if I want to make it 6D it's not OK? I agree that you need to be careful if using 20D, but a small increase should not matter and it can help. And if tomorrow code changes and says that a standard bend diameter is 6D, do you think we'd suddenly see a huge number of damaged buildings because of that?

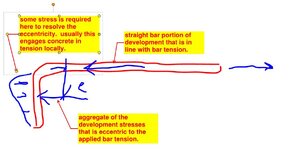

And that eccentricity often is a problem in the sense that, in many cases, that is resolved via some version of relying on concrete in tension, which we generally try to avoid when possible.

What tension are you referring to exactly, it's hard to follow this part for me.

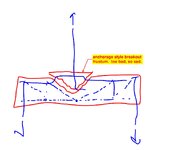

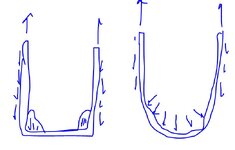

Frankly, I don't feel that a hoop would perform all that much better than a pair of inward facing hooks.

Maybe in this case both can be used, it depends on the specifics I guess.

But generally speaking a hoop can only fail by bursting in a perpendicular direction, it can not open and as you mentioned before "bends tend to unbend". It's a huge difference.

Eurocode (if I'm interpreting it correctly) says that a hoop is by default anchored, no need to check it. Leonhardt said something like anchorage length = 3D so it is a huge difference to the standard hook.

But I guess OP could place transverse bars to decrease the anchorage. Does that work?

www.eng-tips.com

www.eng-tips.com