Hello everyone. I'll keep this as short as possible. I am a member of several forums, it's a challenge to find educated professionals fluent in structural welding code. I have been on a welding torch for 15 years, since I was 19, various fabrication jobs involving low carbon steels, stainless steels, and I have been lead welder of aluminum at my company for the last 8 years or so. I figured the CWI exams were the next logical step... I put it off for quite a while because the study materials are quite intimidating, not to mention that nothing about the AWS is cheap. (I'm in over $4000 pass or fail at this point) I finally pulled the trigger on the whole thing, D1.1 seminar/exam end of next month. I have been neck deep in the books ever since. I did pretty good in High school, but at 33 years old, it's getting to where that was kind of a long time ago. The Aws D1.1 code book is highly technical, but after 15 years of welding and a history of interest in design, most of it is fairly intuitive. There are a few things that are a little sketchy for someone like me that is "self studying" without anyone to walk me through it.

My question today is regarding figures 6.1 - 6.3.

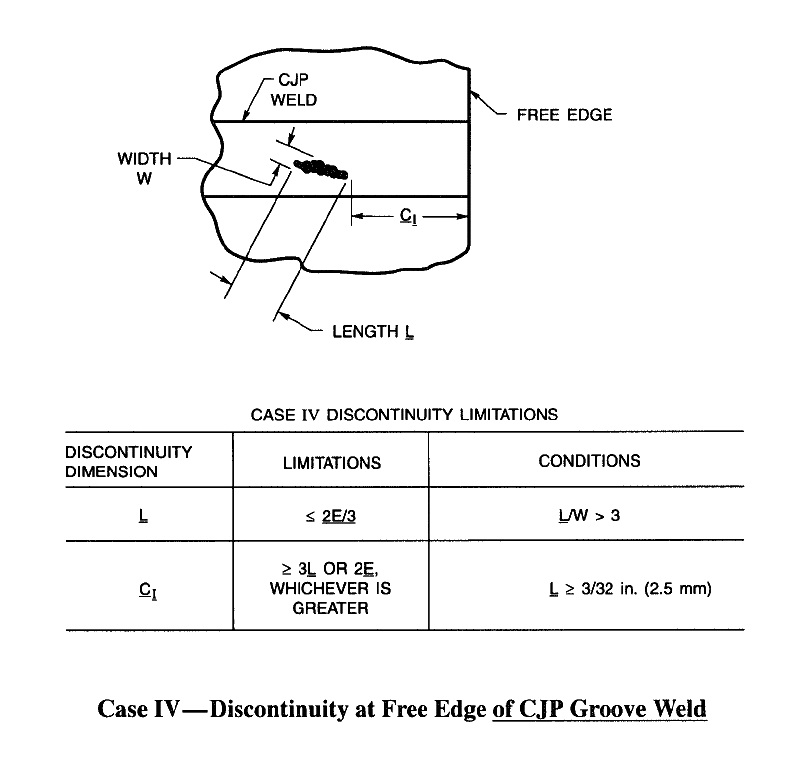

After the graphs, there are a series of diagrams accompanied by simple tables divided into 3 columns: Discontinuity dimension, limitations, and conditions.

In this case, I am interpreting "limitations" to mean "~Shall Be", and "Conditions" to mean "~When"

I am a little confused as to the meaning of the word "conditions" as it is intended here. In Fig 6.1, Case I and II the "conditions" column references "E"(weld size) but in Case III the "conditions" column references "L" and "W" (length and width of said discontinuity).

I am just trying to make sure I understand what they are trying to say here... any help to break down this set of figures in simple terms would be MUCH appreciated. Thank you in advance.

Like I said, I am not an engineer, just a highly experienced welder diving into the technical side of the trade, with a hobbyist level interest in design. Call me an enthusiastic amateur.

My question today is regarding figures 6.1 - 6.3.

After the graphs, there are a series of diagrams accompanied by simple tables divided into 3 columns: Discontinuity dimension, limitations, and conditions.

In this case, I am interpreting "limitations" to mean "~Shall Be", and "Conditions" to mean "~When"

I am a little confused as to the meaning of the word "conditions" as it is intended here. In Fig 6.1, Case I and II the "conditions" column references "E"(weld size) but in Case III the "conditions" column references "L" and "W" (length and width of said discontinuity).

I am just trying to make sure I understand what they are trying to say here... any help to break down this set of figures in simple terms would be MUCH appreciated. Thank you in advance.

Like I said, I am not an engineer, just a highly experienced welder diving into the technical side of the trade, with a hobbyist level interest in design. Call me an enthusiastic amateur.