Hi Everyone,

I have a Generator Step Up (GSU) Transformer with the HV side at 240kV. The high side terminations are via 'plug-in' bushings that only allow for termination of a 240kV power cable.

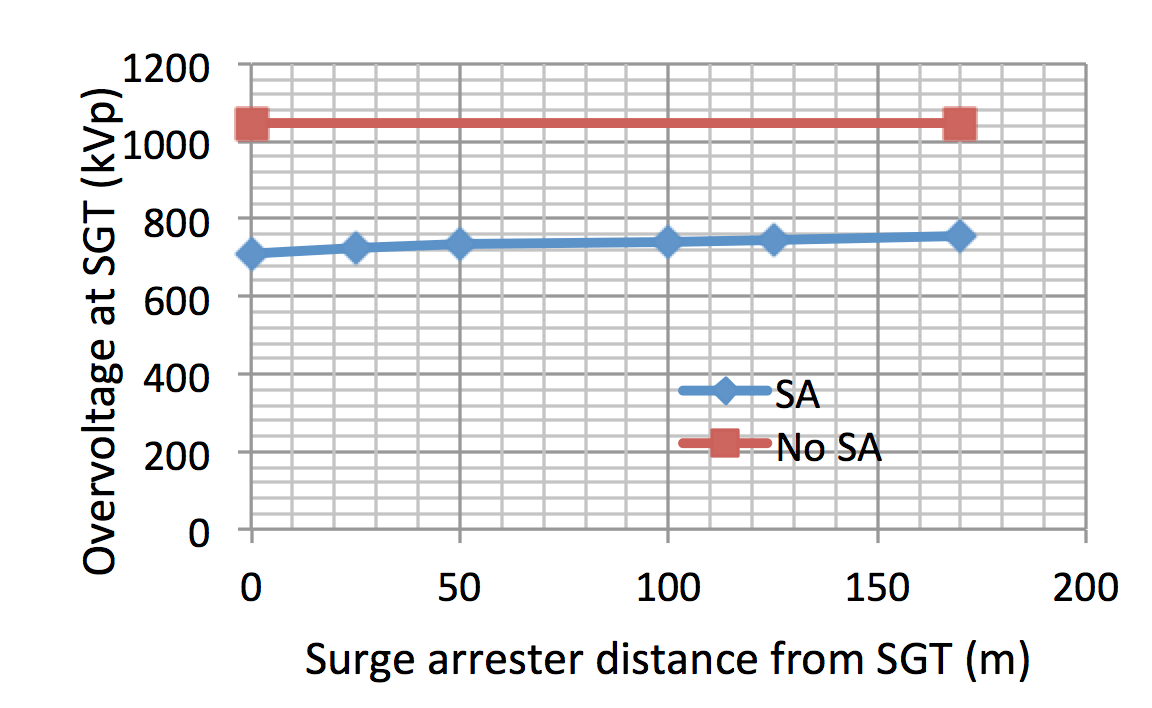

My concern is with placement of a surge arrester for Transformer protection. In a standard air bushing configuration, the Surge Arresters are located right next to the transformer bushing and within the required separation distance (calculated per IEEE C62.22). However, in this configuration, the closest surge arrester will be about 30m away where the 240kV cable terminates on a transmission line receiving structure. Per my calcs using IEEE C62.22 (App C), max allowable separation is about 20m.

My query is whether a 'internal' type surge arrester can be installed directly into the transformer and right next to the terminations? Has anyone had any experience with such installations? So far we have not received a positive reply from the GSU manufacturer.

I have a Generator Step Up (GSU) Transformer with the HV side at 240kV. The high side terminations are via 'plug-in' bushings that only allow for termination of a 240kV power cable.

My concern is with placement of a surge arrester for Transformer protection. In a standard air bushing configuration, the Surge Arresters are located right next to the transformer bushing and within the required separation distance (calculated per IEEE C62.22). However, in this configuration, the closest surge arrester will be about 30m away where the 240kV cable terminates on a transmission line receiving structure. Per my calcs using IEEE C62.22 (App C), max allowable separation is about 20m.

My query is whether a 'internal' type surge arrester can be installed directly into the transformer and right next to the terminations? Has anyone had any experience with such installations? So far we have not received a positive reply from the GSU manufacturer.