I think it's in the scope of IRC way at the beginning.

Also bear in mind that the IRC in general (and the prescriptive equivalent in the IBC in Chapter 23) are not engineered and are based on "historical successful practice"" or whatever the term is. You're trying to compare cook by feel with a log stove to a twinkie manufacturing plant. Or maybe grandma's sourdough with wonder bread. Then again that kind of disparages the wrong item. It's like comparing rat infested RV "diner" with an A rated McDonalds in New York City where it's inspected frequently. There.

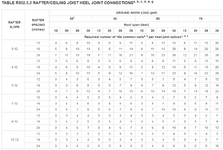

Make sure whatever you design isn't less than what any of the IRC tables say, but if your design says you need more, bigger, or stronger, go with your design. For instance, if a rafter to ceiling joist connection calcs at saying I need 4 nails, but the IRC says 6, I'm going to specify 6.

I think you're in the minority there, and the IRC does not override an engineered design, further when it comes to connections, some spots in the IRC call for unworkably large numbers of nails as it was produced by some guy with a spreadsheet and no practical thoughts. And the provision got voted on by the body of the IRC not the engineers.

One could potentially put 21 nails to connect a pair of 2x4s at 45 degrees (rafter to ceiling joist table) but the wood will split and you'll have no established strength value.

So blindly using the IRC as a minimum after your calculation isn't generally wise.

they can hold you (or the company you work for) responsible for poor serviceability regardless of code minimums.

Not really. You are wildly overselling that. Anybody can sue anybody for anything, it's the ones that survive summary judgement as a complaint against a design professional (i.e. with another engineer swearing the suit has merit) that have teeth. Now, your insurance company may settle to make it go away, that's another story. I haven't seen any floor vibration lawsuits in residential construction "land". Also, establishing some level of vibration performance as actually in a statute, or as a standard of care, that's another challenge for the prosecution.

Incidentally, the older stud tables in the IRC used to have a required modulus of elasticity that only Red Maple could meet as stud grade, as I recall. That MOE requirement disappeared a while ago. Never did track down the code change amendment or when it happened, but it was probably that guy at Reid Middleton who submits hundreds of code changes each cycle. The man's stamina astounds me.

Relevant (somewhat) discussion from earlier this year:

What are the limits of prescriptive design

There was an instance of the IRC more clearly (and strictly) defining anchor bolt spacings for sill plates several years ago. The NAHB (and/or other similar bodies) lobbied all the states to reject the code or edit that part out. It was gone in the next code cycle, back to 6' on center for pinned basement wall connections to a wood floor. Yikes.

There's an FAQ on that over in the wood forum, it's related to unrealistic values from ACI 318-99 appendix D that came out in 2000 after the 2000 IRC was publsihed using the not yet published Appendix D which came out in 2000. Anyway, actual research was done (by SEAOC, not some lobbyists group) and the code eventually got more realistic.

Braced wall anchorage as I recall is how 4 feet which is tighter than the generic wall at six feet as well.

Most places the required insulation in walls determines the wall thickness not structural design.

Only in the North. With the wind load concern I'm speculating our OP is in Florida or the (warm) Atlantic coast.

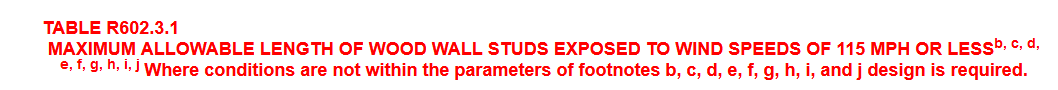

OP the stud tables probably don't apply, there is a lot of fine print most engineers just don't have the patience to read. Particularly if your design is saying you need more, either for wall finish or for loads.

Last item, Minnesota's code for a fair number of years has had stud tables that go away fair bit beyond the IRC so you may find those interesting as a back check or merely for the oddity of something so structural in the residential code. I practice in Minnesota and even I forget those tables exist, since I think the 2007 Minnesota Residential Code. Exposure C and D as well if I recall.

Sorry if anybody got forty notices about new posts in this thread, I'm on my phone. Should be doing something more productive but I'm not.