AtticusMech

Mechanical

- Aug 24, 2017

- 4

Looking to get clarity on something that has bothered me for years. There seems to be a giant misalignment that nobody talks about with threaded weld-on branch fittings (threadolets) per MSS SP-97 vs ASME B16.11's class system.

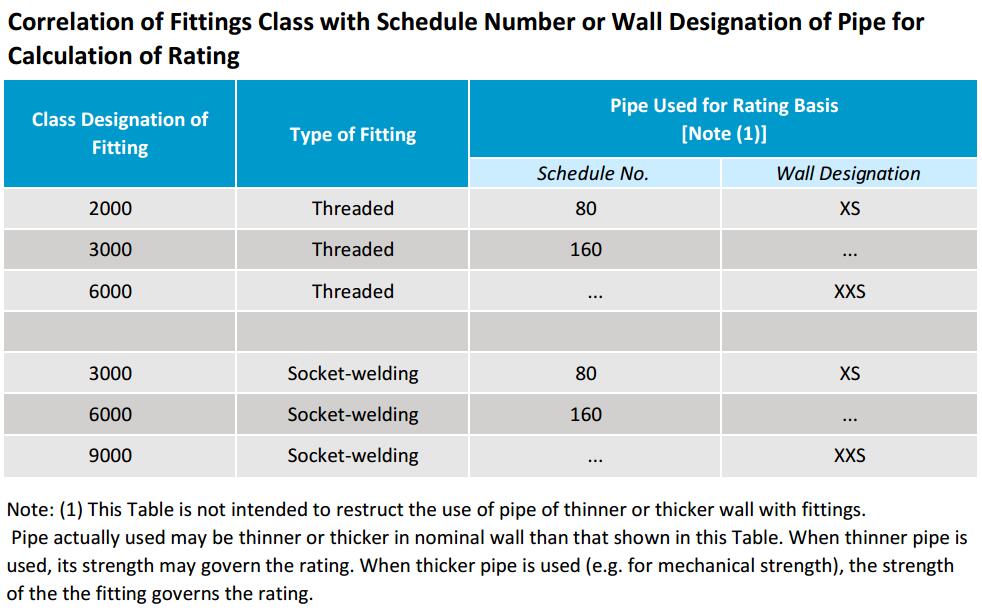

First, for most threaded fittings covered by ASME B16.11, Table 7 provides the basis for how pressure ratings are determined. Class 2000, 3000, and 6000 fittings have pressure rating matching Sch 80, 160, and XXS pipe respectively. Then Clause 2.1.1 explains that you still need to reduce wall thickness by applicable allowance (e.g. thread depth, corrosion). So a Class 3000 threaded fitting per ASME B16.11 is equivalent to a Sch 160 pipe minus thread allowance and corrosion.

But then MSS SP-97, rather than referencing the ASME B16.11 system makes it's own. Table 1 of this code defines Class 3000, 6000, and 9000 threaded fittings (9000 added in 2019 code) to match Sch 80, 160, and XXS pipe respectively. Again Clause 2.2 and 2.3 mention you need to remove wall thickness allowance for things like threading and corrosion. So a Class 3000 threaded fitting per MSS SP-97 is equivalent to a Sch 80 pipe minus thread allowance and corrosion. A totally different pressure rating.

Each of these codes make sense on their own but the differing uses of Class 3000 and 6000 is excessively confusing and I always get some very confused looks when I try to mention this to others. I have reviewed numerous client's piping specifications and noticed they don't account for this and generically specify Class 3000 fittings.

I'm curious on other people's takes on this? Have you noticed this also? Am I interpreting things incorrectly?

First, for most threaded fittings covered by ASME B16.11, Table 7 provides the basis for how pressure ratings are determined. Class 2000, 3000, and 6000 fittings have pressure rating matching Sch 80, 160, and XXS pipe respectively. Then Clause 2.1.1 explains that you still need to reduce wall thickness by applicable allowance (e.g. thread depth, corrosion). So a Class 3000 threaded fitting per ASME B16.11 is equivalent to a Sch 160 pipe minus thread allowance and corrosion.

But then MSS SP-97, rather than referencing the ASME B16.11 system makes it's own. Table 1 of this code defines Class 3000, 6000, and 9000 threaded fittings (9000 added in 2019 code) to match Sch 80, 160, and XXS pipe respectively. Again Clause 2.2 and 2.3 mention you need to remove wall thickness allowance for things like threading and corrosion. So a Class 3000 threaded fitting per MSS SP-97 is equivalent to a Sch 80 pipe minus thread allowance and corrosion. A totally different pressure rating.

Each of these codes make sense on their own but the differing uses of Class 3000 and 6000 is excessively confusing and I always get some very confused looks when I try to mention this to others. I have reviewed numerous client's piping specifications and noticed they don't account for this and generically specify Class 3000 fittings.

I'm curious on other people's takes on this? Have you noticed this also? Am I interpreting things incorrectly?