sdz

Structural

- Dec 19, 2001

- 562

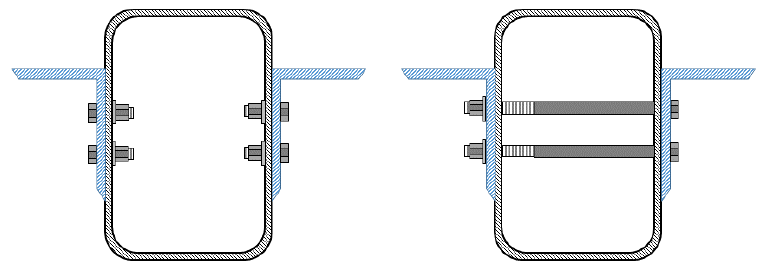

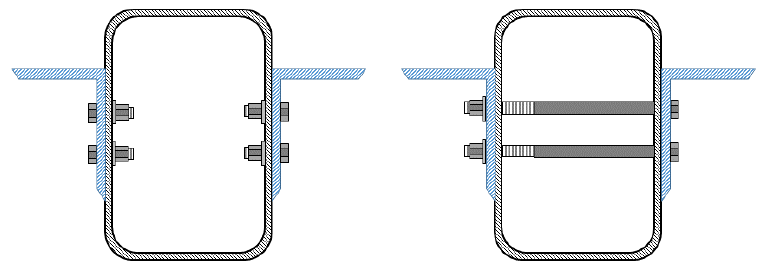

Can anyone direct me to a design guide for a through bolt connection to a CHS? E.g. see below where the CHS is in tension/compression. Since there is no bolt head/nut on the inside of the CHS to clamp the joint I understand the capacity can be lower than for a normal connection, however the curvature should mean it is not prone to local buckling like a flat plate. I've already looked at CIDECT Design Guide 9. I read the reference below but it talks mainly about RHS.

Ref: "Connecting Hollow Structural Section Members with Through-Bolts"

steeltubeinstitute.org

steeltubeinstitute.org

Ref: "Connecting Hollow Structural Section Members with Through-Bolts"

Connecting Hollow Structural Section Members with Through-Bolts | Steel Tube Institute

In this article, Jason McCormick, Associate Professor, Civil & Environmental Engineering, University of Michigan, discusses how to connect HSS section members with through-bolts.