Skazak

Structural

- Jun 25, 2007

- 8

For an isolated shear wall, how do you go about calculating the uplift force at the end of the wall panel?

My question specifically is how do you go about applying dead load to your wall to resist the uplift. This is the dead load derived from the load equation 0.6D + W/0.7E.

I have run into two methods for calculation this value:

1) The typical method for this calculation is to find the dead load of the entire shear panel as well as any dead load supported by this wall. This load is applied at its own centroid and is used in a moment equation to resist the uplift force calculated from the applied lateral load.

2) The second method I have seen is to only apply the dead load that is tributary to the shear wall chord that is subjected to the uplift. ie. for a typical wall with studs at 16” o.c. only an 8” width of wall dead load and 8” of the dead load supported by the wall are used to resist the uplift.

While method (2) is obviously extremely conservative, I can find no concrete evidence supporting the use of the method (1).

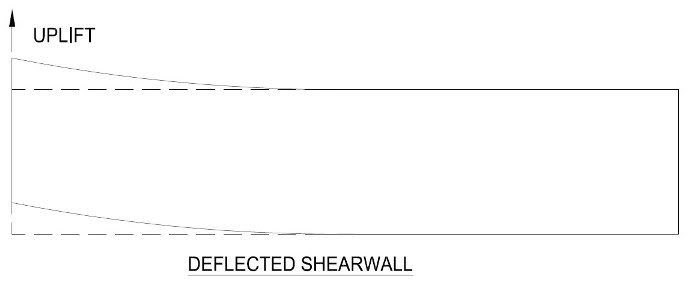

Method (1) really begins to break down when the shear wall panel is significantly longer then it is high. In this case, the wall is going to deflect under the uplift force and would therefore not be engaging its full dead load to resist.

Does anyone know of any testing or research done into how much of a wall dead load can realistically be expected to resist the uplift? I shudder to think of the strapping that will result from the use of method (2), but without some justification, do I have a choice?

Thanks for your help.

My question specifically is how do you go about applying dead load to your wall to resist the uplift. This is the dead load derived from the load equation 0.6D + W/0.7E.

I have run into two methods for calculation this value:

1) The typical method for this calculation is to find the dead load of the entire shear panel as well as any dead load supported by this wall. This load is applied at its own centroid and is used in a moment equation to resist the uplift force calculated from the applied lateral load.

2) The second method I have seen is to only apply the dead load that is tributary to the shear wall chord that is subjected to the uplift. ie. for a typical wall with studs at 16” o.c. only an 8” width of wall dead load and 8” of the dead load supported by the wall are used to resist the uplift.

While method (2) is obviously extremely conservative, I can find no concrete evidence supporting the use of the method (1).

Method (1) really begins to break down when the shear wall panel is significantly longer then it is high. In this case, the wall is going to deflect under the uplift force and would therefore not be engaging its full dead load to resist.

Does anyone know of any testing or research done into how much of a wall dead load can realistically be expected to resist the uplift? I shudder to think of the strapping that will result from the use of method (2), but without some justification, do I have a choice?

Thanks for your help.