Vrpeng-tips

Mechanical

- Sep 4, 2015

- 14

Hello,

Unit - Div.1 U-Stamp heat exchanger

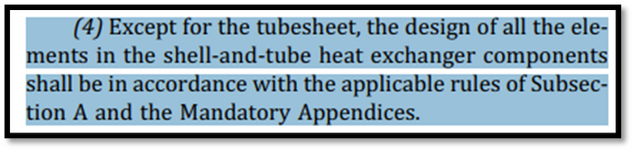

Most of the design of the unit can be done using div.1 rules (Shell, Nozzles, head,etc..)

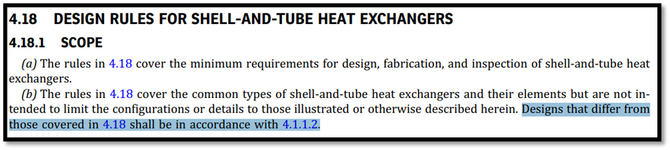

For a fixed tube sheet div.2 part 4.18 applies. And design can be completed using DBA.

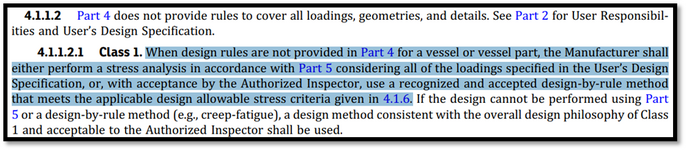

In a rare case when we have tube sheet geometry out of scope and there is need for thickness validation, do we absolutely have to do DBA per div.2 part 5?

Or we can do the FEA and validate the T.S thickness and stress per div.2 part 4?

Thank you in advance.

Unit - Div.1 U-Stamp heat exchanger

Most of the design of the unit can be done using div.1 rules (Shell, Nozzles, head,etc..)

For a fixed tube sheet div.2 part 4.18 applies. And design can be completed using DBA.

In a rare case when we have tube sheet geometry out of scope and there is need for thickness validation, do we absolutely have to do DBA per div.2 part 5?

Or we can do the FEA and validate the T.S thickness and stress per div.2 part 4?

Thank you in advance.